|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

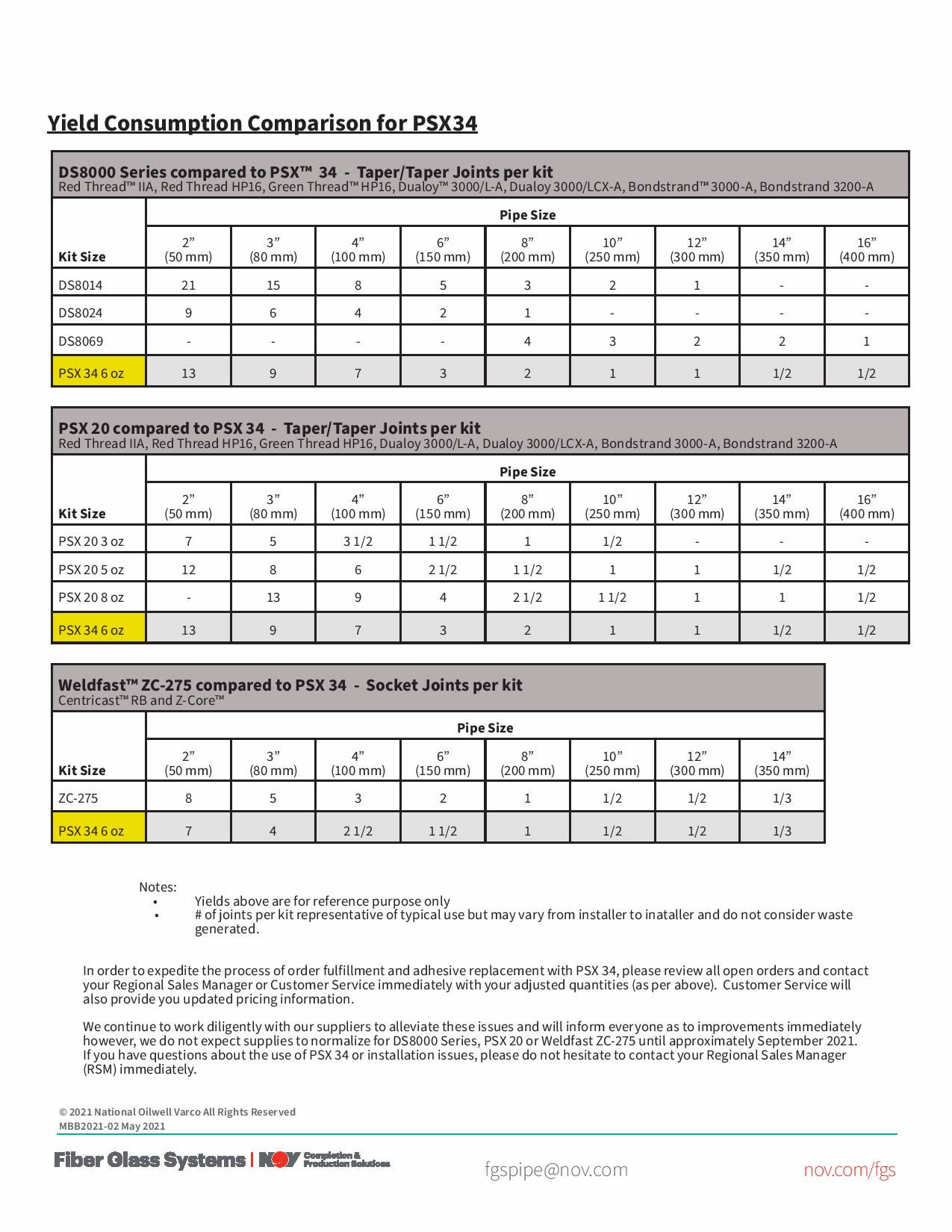

EVO™ 200 & EVO™ 400: Automatic Tank GaugesEVO™ 200 & EVO™ 400 Automatic Tank Gauges (ATGs) provide highly accurate inventory management and containment monitoring for small to mid-size fuel systems. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

NEVER STOP EVOLVINGWe are driven by our pursuit to innovate, simplify, secure, and connect every station owner to their fuel management system. EVO™ 200 & EVO™ 400 ATGs feature simple setup and operation, remote connectivity, and advanced security features to protect your fuel system while keeping you directly connected to vital site data whenever, and wherever. Highly CapableEVO™ 200 & EVO™ 400 allow you to make informed, data-driven inventory management decisions with features like, inventory monitoring, tank testing, and containment compliance monitoring. Simple InterfaceA full-color 7” LCD touchscreen serves up one of the most intuitive user interfaces available with simplified user features you won’t find anywhere else. Secure DataEVO™ Series ATGs keep your site in compliance and protected from security threats with customizable user roles, user activity tracking, and up to 3-years of data back-up to protect against power outages or other system interruptions. TECHNICAL ADVANTAGES

SIMPLICITY & VISIBILITYA full-color 7” LCD touchscreen serves up one of the most intuitive user interfaces available with simplified user features you won’t find anywhere else. You choose your home screen, you program your product colors, and you choose what shows up on your Favorites screen. Customize the interface to meet your business needs the way you operate.

SYSTEM SECURITYEVO™ Series ATGs help keep sites in compliance while providing marketers with the highest level protection from the security threats facing our industry.

REMOTE CONNECTIVITYThe FFS PRO® Connect web interface allows you to securely connect directly to your EVO™ Series ATG from any web enabled device. It automatically scales for tablets and smart phones, meaning no app to download.

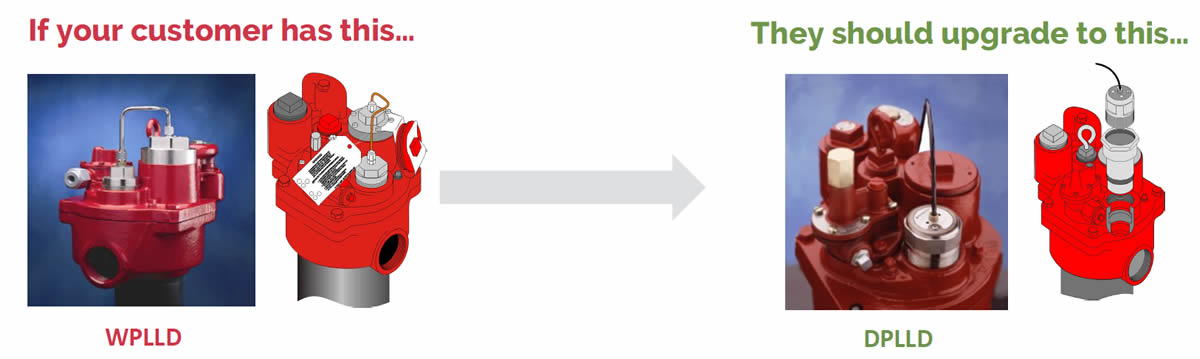

TURBINE PUMP INTERFACETurbine Pump Interface is a powerful tool that creates a network between your Submersible Turbine Pump (STP) controllers and EVO™ Series ATGs. Through TPI, the tank gauge can be programmed to respond to faults in the submersible pumping system and react with intelligence that pump controllers alone cannot.

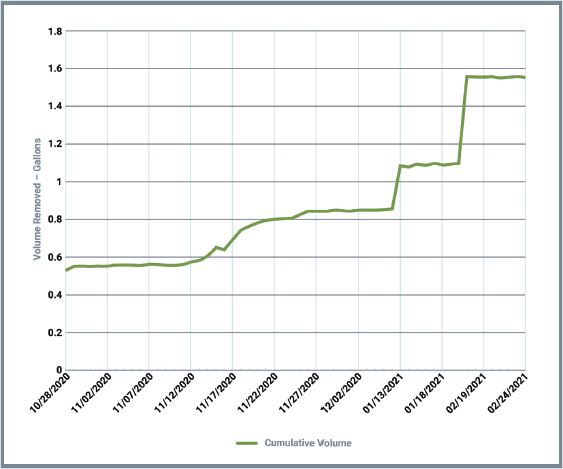

FLOW RATE MONITORINGImprove dispenser throughput and maintain fast flow rates with the ability to detect and react to potential slow flow issues before they impact business with Flow Rate Monitoring. Available as a software option on new EVO™ Series ATGs or as a field upgrade option, Flow Rate Monitoring delivers ongoing flow rate performance data, flow rates for each fueling point, and provides a notification if transactions dip below a user-defined set point.

FIND THE RIGHT EVO™ SERIES ATG FOR YOUR SITEThe EVO™ Series family of ATGs offers four different options with right-sized features to meet the requirements of your specific application, size, and compliance needs. Which ATG is right for your application?

Components

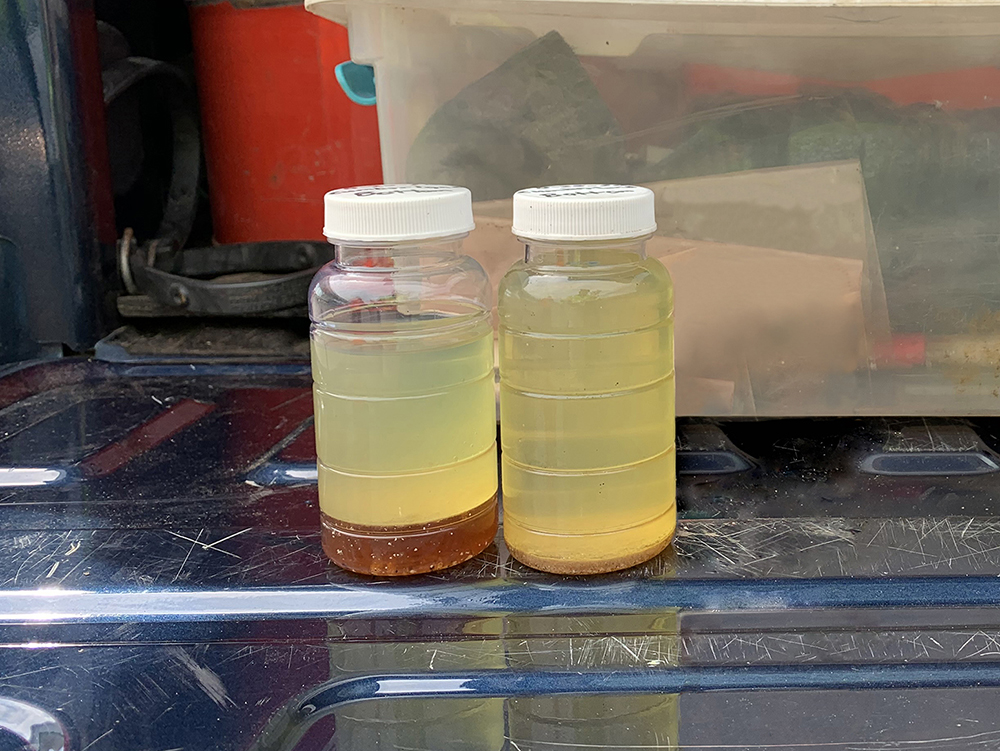

General• Maximum tanks monitored: 6 (EVO™ 200) / 14 (EVO™ 400) • Maximum sensor input capacity: 6 (EVO™ 200) / 14 (EVO™ 400) • Total # of inputs: 6 (EVO™ 200) / 14 (EVO™ 400) • Dry contact input channels: 2 • Relay output channels: 2 • Connectivity: Ethernet, RS-232, RS-485, standard USB, mini USB, and Wifi (optional) • Display type: 7” (17.78 cm) color LCD touch screen • Printer support: External (network or USB) • Alarm: Internal audible alarm • LEDs: Alarm, warning, and power • Tank chart correction points: 7,500 • Applicable liquids: Petroleum, chemicals, and waste oil • Level units: Inches, centimeters, and millimeters • Volume units: gallons or liters (mass with density option) • Power requirements: 110 to 240 VAC, 50/60 hz, 1.0 Amps max. • Operating temperature: 32° to 104 °F (0° to 40 °C) • Humidity: 0-90% non-condensing • Dimensions: Height: 8” (205mm), Width:13 ¾” (350mm), Depth: 3¼” (83mm) Capabilities• High/low product, water, and temperature alarm set points • Inventory reconciliation / tank auto-calibration / flow rate monitoring (optional) • Density, mass, and phase separation measurement • Email and SMS notifications • Back-up generator monitoring • MODBUS™ support Approvals/Certifications• UL, cUL, ATEX, IECEx • Third party certification of leak detection capabilities |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

If you have any questions about Franklin Fueling Systems EVO ATGs or would like to receive a quote, please feel free to contact us at 1-800-451-4021 or Email Us with any further questions or inquiries.

The John W. Kennedy Company appreciates your business and continued support!

ADD ITEMS TO TRANSACTION

ADD ITEMS TO TRANSACTION ATTENDANT AUDIO ALARM

ATTENDANT AUDIO ALARM AUTHORIZE AGE RESTRICTED ITEM

AUTHORIZE AGE RESTRICTED ITEM