End of Life Notification

Overview

Veeder-Root is committed to providing the highest quality products and services to our customers.

As part of the natural cycle that drives technology evolution, Veeder-Root is announcing the Global

End of Life (EOL) for the following Red Jacket legacy products. Expected availability dates (subject

to change based on supply availability) and EOL scope are outlined below:

No longer available

• Red Jacket Touch Up Paint – Global EOL

June 30, 2022 – Available while supplies last

• Red Jacket Fixed Length STP Final Assemblies 60Hz – 11’1” to 19’9” – Global EOL

Red Jacket Touch Up Paint

Veeder-Root is announcing the Global End of Life of the Red Jacket Touch Up Paint, due to very

limited demand.

| End Of Life Timeline |

The touch up paint is no longer available.

Impacted Products

| Part Number | Description |

| 0410913-001 | KIT-TOUCH UP PAINT |

| 0410910-001 | PAINT-TOUCH UP – RED ARMOR® |

Impacted Red Jacket Fixed Length STP Final Assemblies 60Hz – 11’1” to 19’9”

Impacted Red Jacket AG Fixed Length STP Final Assemblies 60Hz

Impacted Red Jacket RA Fixed Length STP Final Assemblies 60Hz

We Are Here To Help

Please feel free to contact us at 1.800.451.4021 or Email Us with any questions or concerns pertaining to this End of Life .

We will work with you to ensure you are supported in this changing product line.

CLICK HERE TO FIND

on our web store!

on our web store!

And remember, if you can’t find what you are looking for, please feel free to contact us at 1.800.451.4021 or Email Us

on our web store!

on our web store!

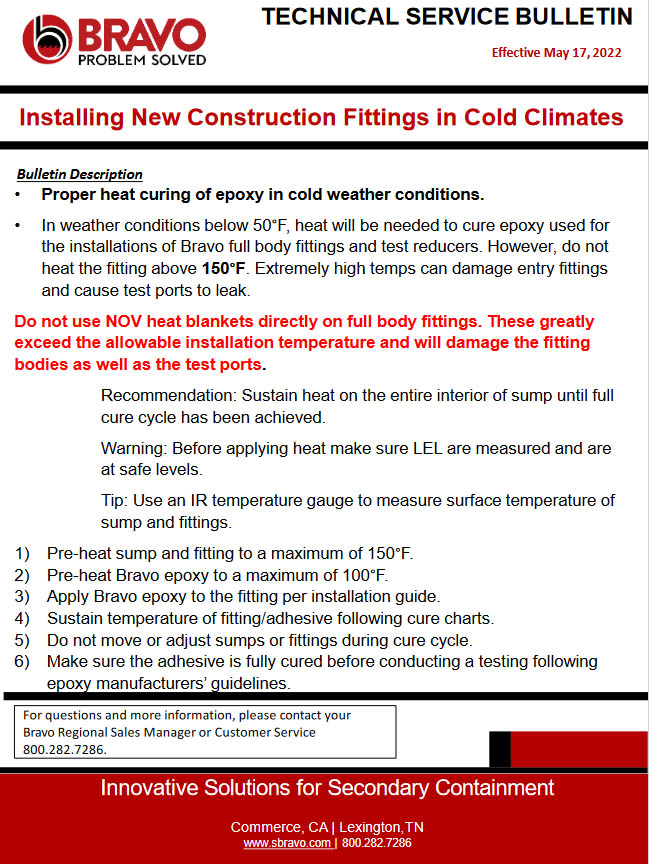

for more product installation and preparation videos

for more product installation and preparation videos