Monthly Archives: January 2021

Upgrading Gas Pumps: How It Makes a Difference

Gas station owners are constantly looking for ways to upgrade and optimize their businesses’ efficiency. Gas pumps are like cars—their value doesn’t diminish when they’re new, but it depreciates once they’re put into use.

Continue readingBehind the scenes of filling up: How does the fuel actually get to the nozzle?

This is Veeder-Root’s third article in their series on what actually happens when you fill up at a gas station. Read the first article here. and the second article here.

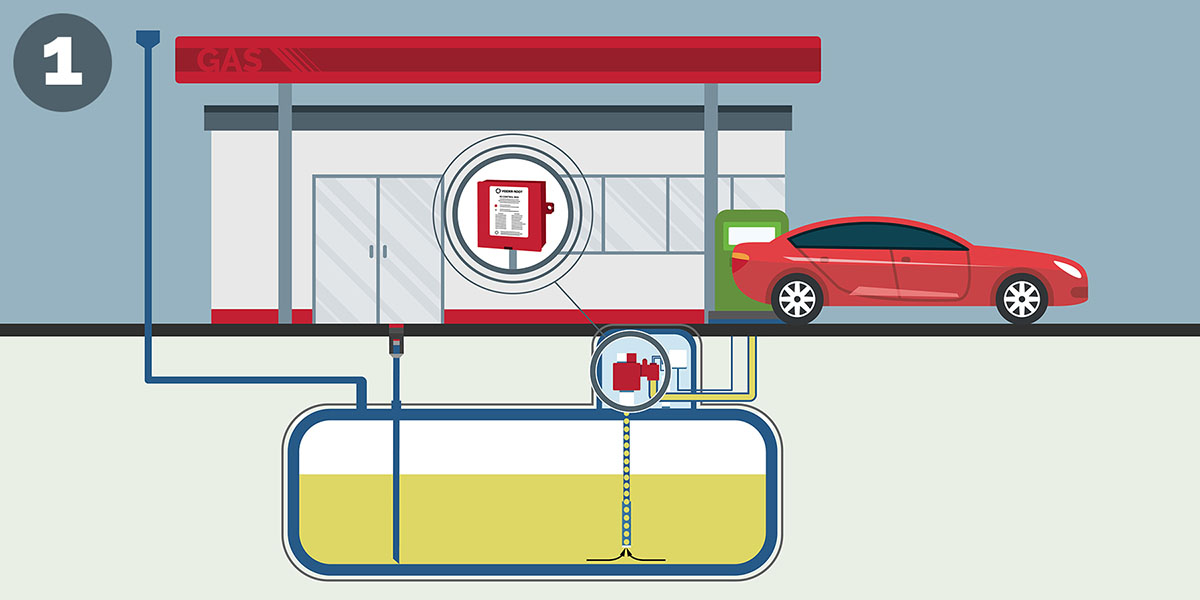

Imagine you’re at a gas station and you’ve started a transaction at a dispenser. Maybe you’ve never given it another thought, but how does the fuel actually get to the nozzle?

The answer is that fuel is pumped up from an underground storage tank via a submersible turbine pump and through the fuel lines to your dispenser nozzle.

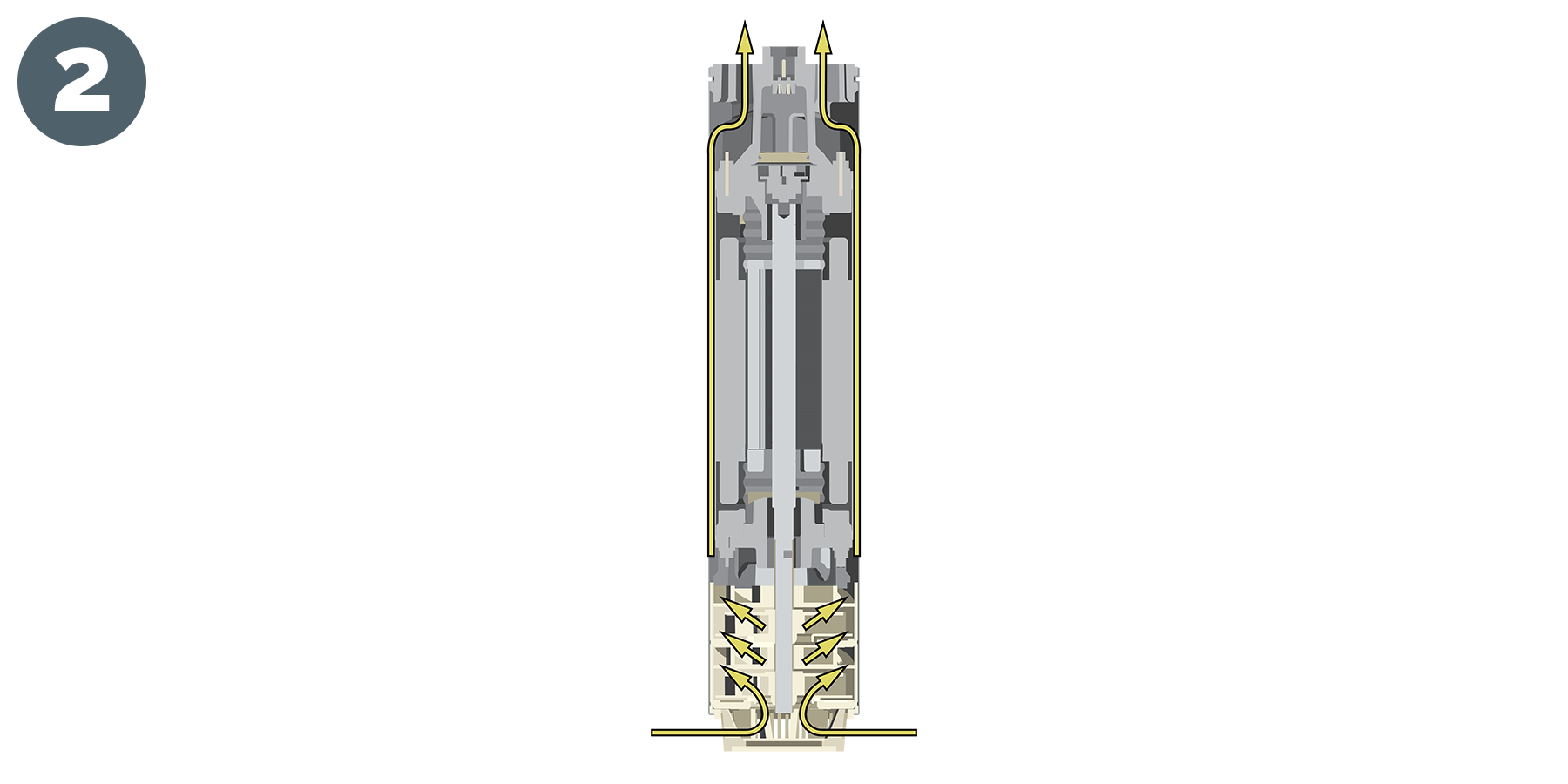

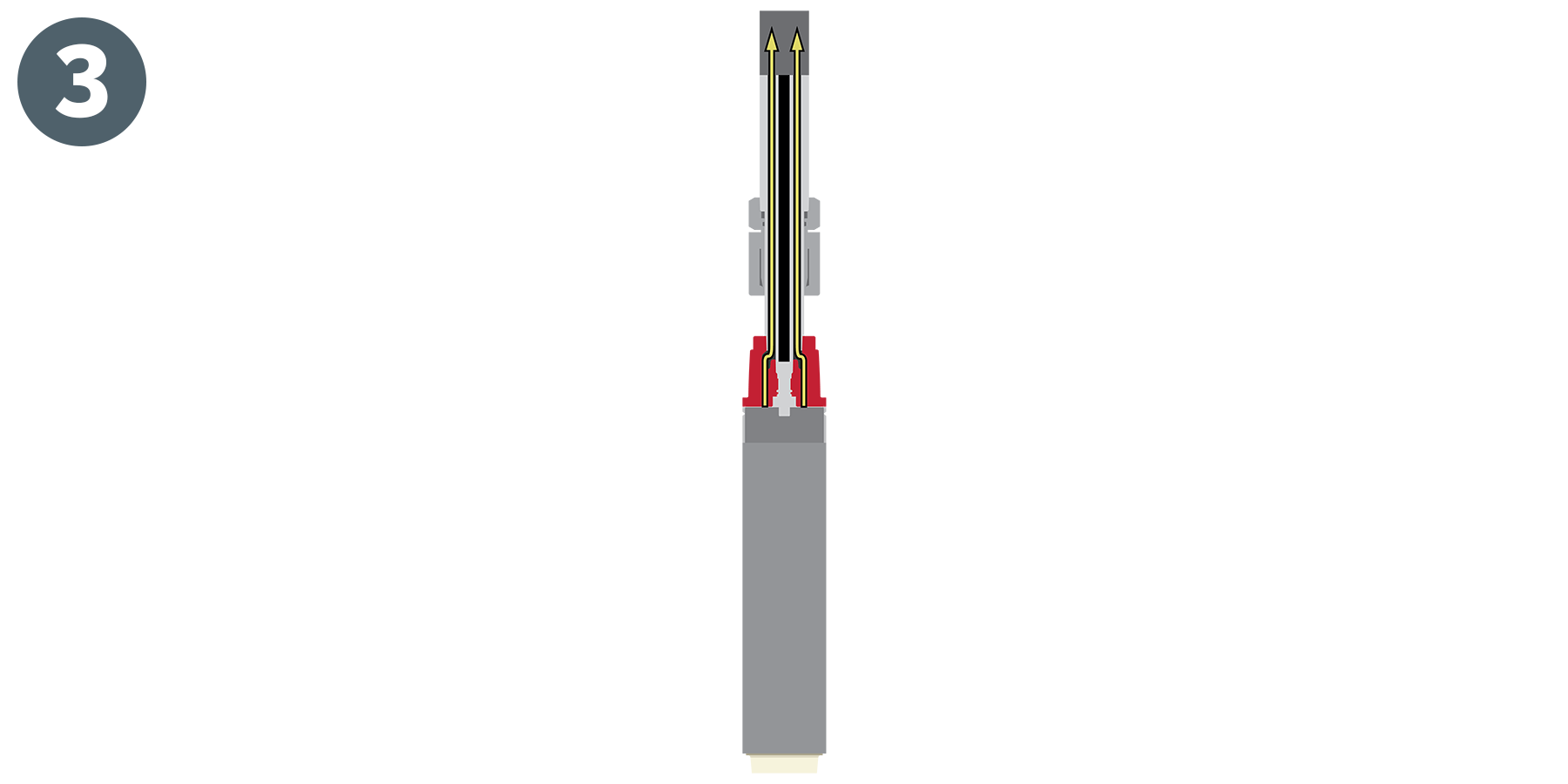

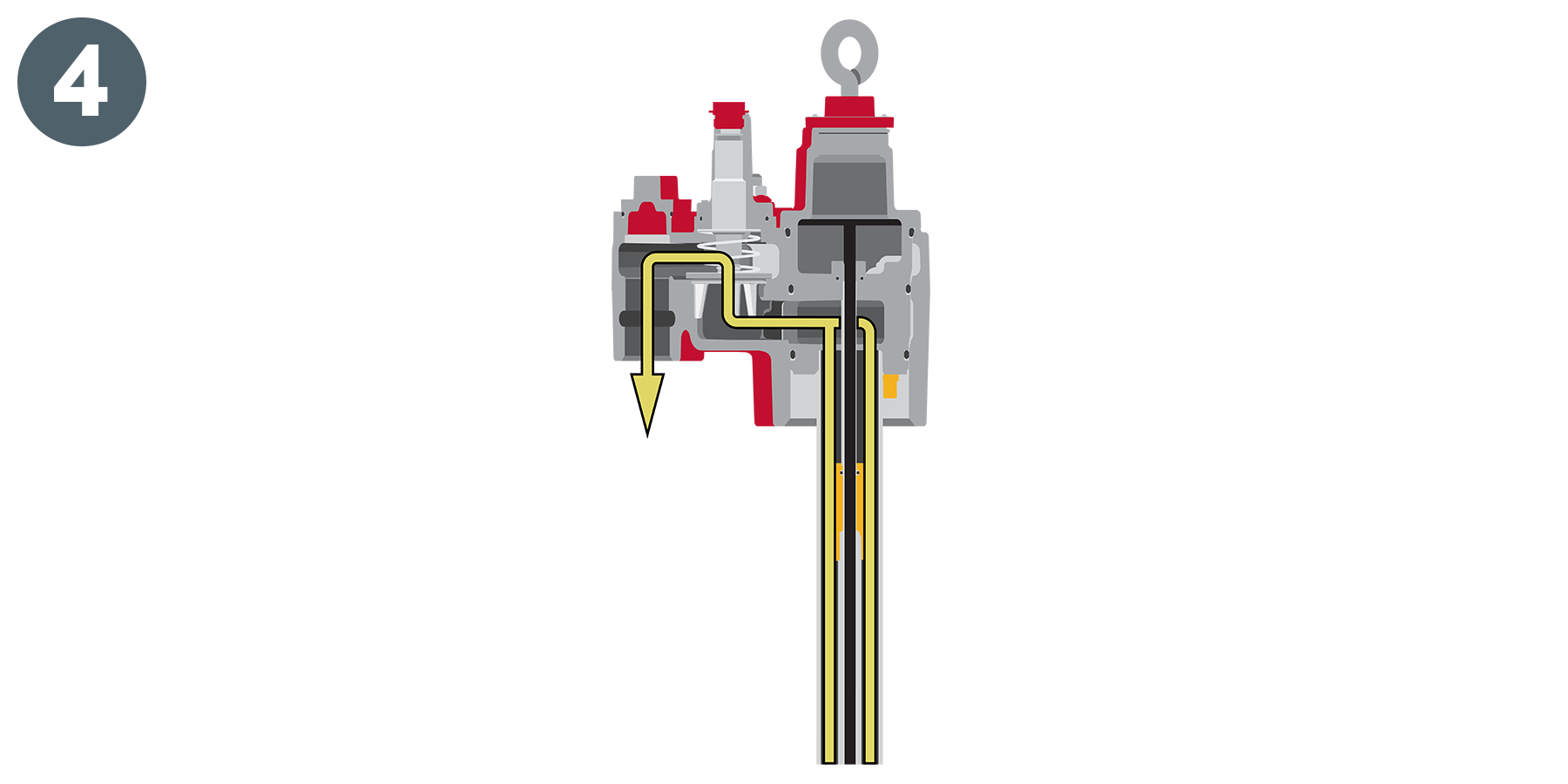

The submersible turbine pump is the powerful unsung hero of the fueling system. These pumps have two main components; a packer manifold which is in the sump space and a Unitized Motor Pump (UMP) that sits down in the tank.

Starting the Flow

- During a transaction, the packer manifold receives the signal and activates the UMP.

- The UMP starts spinning and that rotational energy creates pressure and moves fuel up through the pump.

- The fuel flows up through the column pipe to the packer manifold.

- Fuel enters the packer manifold and goes through a check valve, which is used to keep pressure in the lines, before being discharged into to the fuel lines.

Keeping Track

While it’s dispensing fuel to your vehicle, the dispenser is keeping track of exactly what you’ve pumped and how much that costs. Once you’re done, there are a series of signals that are managed through the automatic tank gauge and control boxes that turn off the STP and finish the transaction.

If using a TLS-450PLUS Automatic Tank Gauge paired with Electronic PLLD, then station operators can also monitor line pressure during the dispense to ensure that system isn’t leaking and meets release detection requirements.

What’s Next?

Next week, we’re discussing how the TLS-450PLUS ATG makes sure the fueling system is free from leaks and compliant with regulatory requirements.

You can find more information on every step of the process here.

If you have any questions or would like to purchase Veeder-Root and Red Jacket Products, visit us online at www.johnwkennedyco.com or call us at 1.800.451.4021.

The John W. Kennedy Company appreciates your business and continued support!

How to Repair a Gas Station Pump

Fuel retailers know the importance of gas station pumps: a malfunctioning pump will send disgruntled customers away. And where will they go? Down the street, to the competition.

Those are two things no fuel retailer wants to happen.

Continue readingBehind The Scenes Of Filling Up: Gaining Approval and Getting Started

This is Veeder-Root’s second article in their series on what actually happens when you fill up at a gas station. Read the first article here.

Most people don’t know this, but a gas station’s fuel dispenser is connected to three primary pieces of equipment that help it run a fueling transaction:

These three pieces of equipment make up the system that manage the transaction, calculate inventory data, and facilitate the pumping of the fuel.

The Gate Keeper

When you lift the handle and start a transaction at the dispenser, nothing happens without the Point-of-Sale System approving it. This is because a POS system must authorize a sale to allow next steps to happen.

The authorization can be done manually by an attendant at the gas station or it can be set to pre-authorization.

Manual authorization means that someone on site must approve all transactions prior to any dispensing. If you’ve ever been at a site where an attendant must pump all gas, this is likely an instance where they’re using the manual settings.

In instances of pre-authorization, the POS system allows a transaction to happen once the payment, usually credit or prepaid fuel card, is approved. If you have ever gone to a 24-hour site that is unattended, this is set to pre-approval.

In either case, the Point-of-Sale System is providing a gate keeper function in the fueling transaction to make sure that only approved fuel dispenses happen.

Sending the Signal

Now that we know the transaction is authorized, the dispenser will reset the displays and get ready to dispense fuel.

In order to create the pressure needed in the fuel lines to dispense it, the Red Jacket® Submersible Turbine Pump will need to be activated.

This is done when the dispenser signals the other key equipment in the process, the ISOTROL 1-8 Control Box, which notifies the TLS-450PLUS ATG. At that point the ATG sends a relay signal to the Red Jacket IQ Smart Control to start the Red Jacket STP and create pressure in the fueling lines.

Now What?

Next week, we’re discussing how the fuel is pumped from the tank and to the dispenser, including the different modes available.

You can find more information on every step of the process here.

If you have any questions or would like to purchase Veeder-Root and Red Jacket Products, visit us online at www.johnwkennedyco.com or call us at 1.800.451.4021.

The John W. Kennedy Company appreciates your business and continued support!

How Does it Work? Behind the Scenes of Filling Up

For most people, getting gas for their vehicle is an unavoidable, routine part of life. We do it because we have to do it.

And while we all know how to operate a gas pump, most don’t realize that there’s a symphony of sensors and probes working together to keep the fuel flowing safely and efficiently.

Today, we’re tackling the first piece of the fueling process, activating the dispenser.

Gas Pump vs. Fuel Dispenser

Yes, there is a big difference between gas pumps and fuel dispensers, even though people use the words interchangeably.

Some countries use gas pumps, which use a pumping device inside the unit to create suction. The pump pulls fuel out of the storage tank and dispenses it through the product lines and nozzles.

In North America, we use fuel dispensers. These units work on a pressurized system using a submersible turbine pump immersed in the underground storage tanks to deliver fuel to the dispenser.

Activating the Dispenser

So what really happens? The customer pulls up to the dispenser, starts a transaction using a Point-of-Sale system like Passport®, removes the nozzle, and selects a grade.

A signal is sent to the Red Jacket® ISOTROL™ 1-8 Control Box. The control box isolates signals from the dispensers, and protects against wiring shorts and phasing issues.

The ISOTROL notifies the TLS-450PLUS Automatic Tank Gauge to activate the Red Jacket® IQ Smart Control Box and submersible turbine pump.

Now What?

Next week, we’re breaking down the authorization process and how Veeder-Root’s integrated site solutions work together to provide a safe and seamless consumer experience at the gas station.

You can find more information on every step of the process here.

If you have any questions or would like to purchase Veeder-Root and Red Jacket Products, visit us online at www.johnwkennedyco.com or call us at 1.800.451.4021.

The John W. Kennedy Company appreciates your business and continued support!

EMV – What Happens When A Station Isn’t Updated

Exclusive EMV Webinar for Gas Station Retailers

Exclusive EMV Webinar for Gas Station Retailers

Creating a Competitive Advantage with EMV Upgrades

JANUARY 13, 2021 | 11:00 AM EST

(10:00 AM CST, 9:00 AM MST, 8:00 AM PST)

OR

JANUARY 13, 2020 | 3:00 PM EST

(2:00 PM CST, 1:00 PM MST, 12:00 PM PST)

Learn how to reduce risk, protect your business, and make the best EMV upgrade decisions.

The Importance of EMV Compliance

With less than 6 months before the deadline, it is extremely important that you begin to plan for the EMV transition. Join us for a step-by-step guide on how to help your business avoid absorbing fraudulent fees for non compliance.

1. How to protect your site, starting today?

2. What equipment do you need to upgrade?

3. What kind of incentives are available?

Looking for Gilbarco equipment? Click on the links below to visit our web store :

Pumps & Dispensers |

Passport Point of Sale |

Forecourt Payment Options |

Forecourt Merchandising |

Click here to search all Gilbarco equipment and parts listed in our web store.

Please do not hesitate to contact us with any of your EMV questions, concerns or to place an order by calling 1.800.451.4021 or visit us online at johnwkennedyco.com for all your petroleum equipment needs.

The John W. Kennedy Company appreciates your business and continued support!

Can The Cold Weather Affect Your Fuel Station?

Things That Should Be on Every Gas Station Owner’s New Year Resolution List

2021 should be the year your gas station business finally invests in EMV compliance—if it hasn’t already. This refers to upgrading your point-of-sale equipment to facilitate EMV technology and support credit card transactions right at the fuel machine. This will make your transactions easier, risk-free, safer, and more transparent.

Continue reading