Join Omntec For Their Next Remote

Web-Based Training

May 1, 2024 @ 9AM or 1PM

Eastern Time

REGISTRATION DEADLINE: April 26th

Don’t hesitate, register today!

CLICK HERE TO REGISTER FOR OMNTEC TRAINING

-p-500.png) If you have not been trained or need recertification on Omntec’s Proteus line, we strongly recommend attending one of their FREE training sessions.

If you have not been trained or need recertification on Omntec’s Proteus line, we strongly recommend attending one of their FREE training sessions.

OMNTEC’s FREE ASC training is a web-based course including an exam that can be completed at your own pace. The training presentation is live and hosted through Zoom. The course is roughly 2.5 hours long.

After you register you will receive an email with links to documents you can reference during the training session and the certification.

The Zoom meeting link will be sent out at the end of the day the week before the training session. Upon completion of both the training and exam, you will be provided a certificate and a wallet card that will be emailed directly to you.

You can find Omntec products in our web store |

Use our Proteus Shop By Image feature |

Feel free to contact us at 1.800.451.4021 or Email Us with any further questions or to place an order!

The John W. Kennedy Company appreciates your business and continued support!

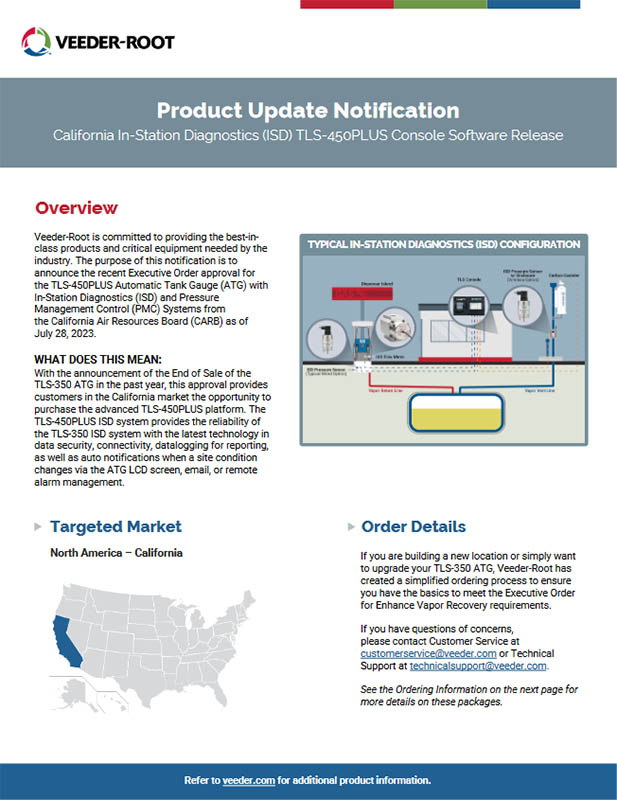

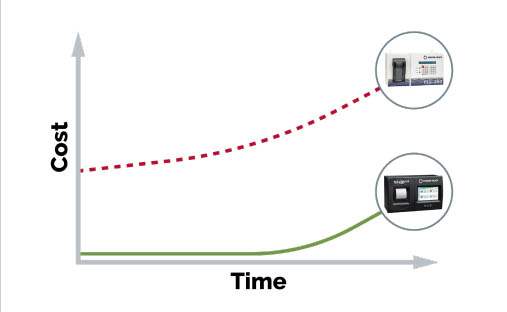

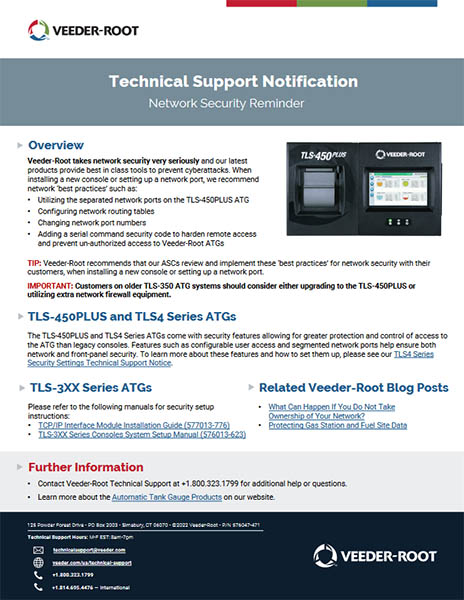

VEEDER-ROOT TECHNICAL SUPPORT NOTIFICATIONS

VEEDER-ROOT TECHNICAL SUPPORT NOTIFICATIONS