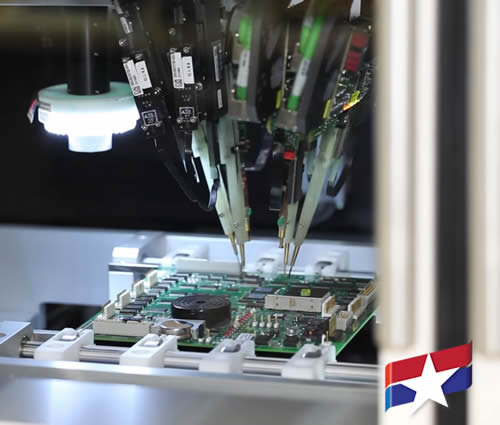

Islander PRIME: Fleet Fuel Management System

Meet the newest addition to the Gasboy family – The Islander PRIME

Islander™ PRIME fleet fuel management system combines the functionality of a sophisticated island fleet card reader in a single package hardened for the fuel island. PRIME Integrates seamlessly with other system components including EKOS and Fleet Head Office management software, also with unattended, remote and automated fueling systems. Create the most reliable, comprehensive turnkey fleet fuel management system on the market. Let Gasboy show you the most advanced fleet control technology — just contact your Gasboy distributor for more information.

• Interfaces seamlessly with Fleet Head Office / Precise cost tracking Supports multiple access technologies, including web-based and contactless systems /

• Easily integrated, enhanced data collection

• Lighted terminals / Secure 24/7/365 availability for unattended sites

ICR PRIME: Island Card Reader

Gasboy’s ICR PRIME island card reader works in tandem with CFN PLUS or the Islander PRIME to provide a cost-effective way to manage access to fuel at multiple islands and unattended sites. Flexible. Efficient. It’s part of your Gasboy complete, turnkey solution backed by the world’s largest network of fleet product distributors and authorized service contractors.

• Compatible with a variety of different driver and vehicle access methods

• Cost-effective solution for multiple fuel islands

• Hardened for the tough fleet environment

Islander EMV PRIME: Payment System For Islander and ICR PRIME® Fleet Fuel Management System

• Insert style Hybrid Card Reader (HCR) reads both chip and magnetic stripe cards

• 16 key pin pad with graphic display and anti-tamper features

• The Payment Card Industry Data Security Standard (PCI DSS) compliant

• Certified for EMV credit transactions on all major card brands including Visa, Mastercard, AMEX, Discover

• Accepts fleet cards including WEX, Voyager, Fuelman

• Accepts proprietary magnetic stripe cards

• Approved on the National Bankcard Services (NBS) Payment Network

Available for new Gasboy systems and field retrofits

• New Islander and Island Card Reader (ICR) PRIME available with the factory-installed EMV option, including hybrid card reader and pin pad

• EMV retrofits for currently installed Islander/ICR PRIME systems

INFORMATIONAL RESOURCES

Gasboy Islander PRIME & ICR EMV Brochure |

Gasboy Homebase Station Brochure |

Gasyboy P-2576 Islander PRIME Product Info Sheet |

Gasboy Islander PRIME FAQ |

Gasboy Fleet and Fuel Management Bid Specification |

Feel free to contact us at please call us at 1.800.238.1225 or Email Us with any further questions, GET A FREE QUOTE or to place an order!

The John W. Kennedy Company appreciates your business and continued support!

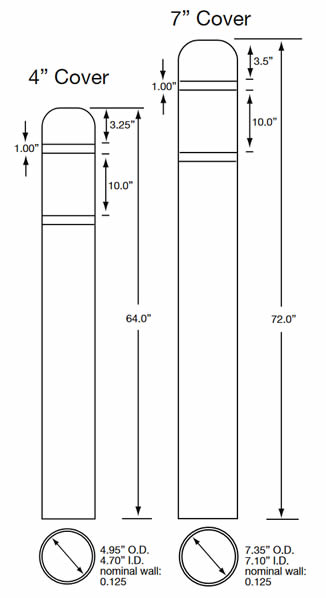

Model 1984-BC Bollard Covers

Model 1984-BC Bollard Covers (HDPE and MDPE) and 3M #680 reflective tape for durability and long service life.

(HDPE and MDPE) and 3M #680 reflective tape for durability and long service life.

Equipment Damage

Equipment Damage

Lost Customers

Lost Customers

Violations & Fines

Violations & Fines