|

|

|||||||||||||||||||||||||||||||||||||||

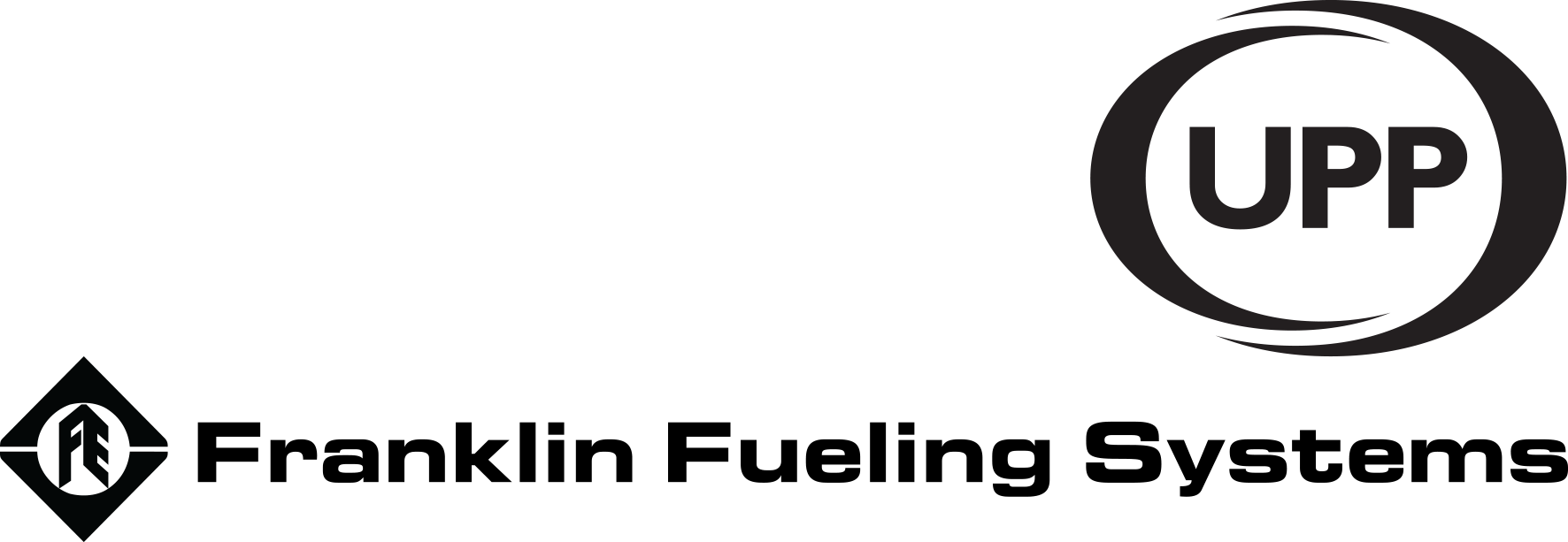

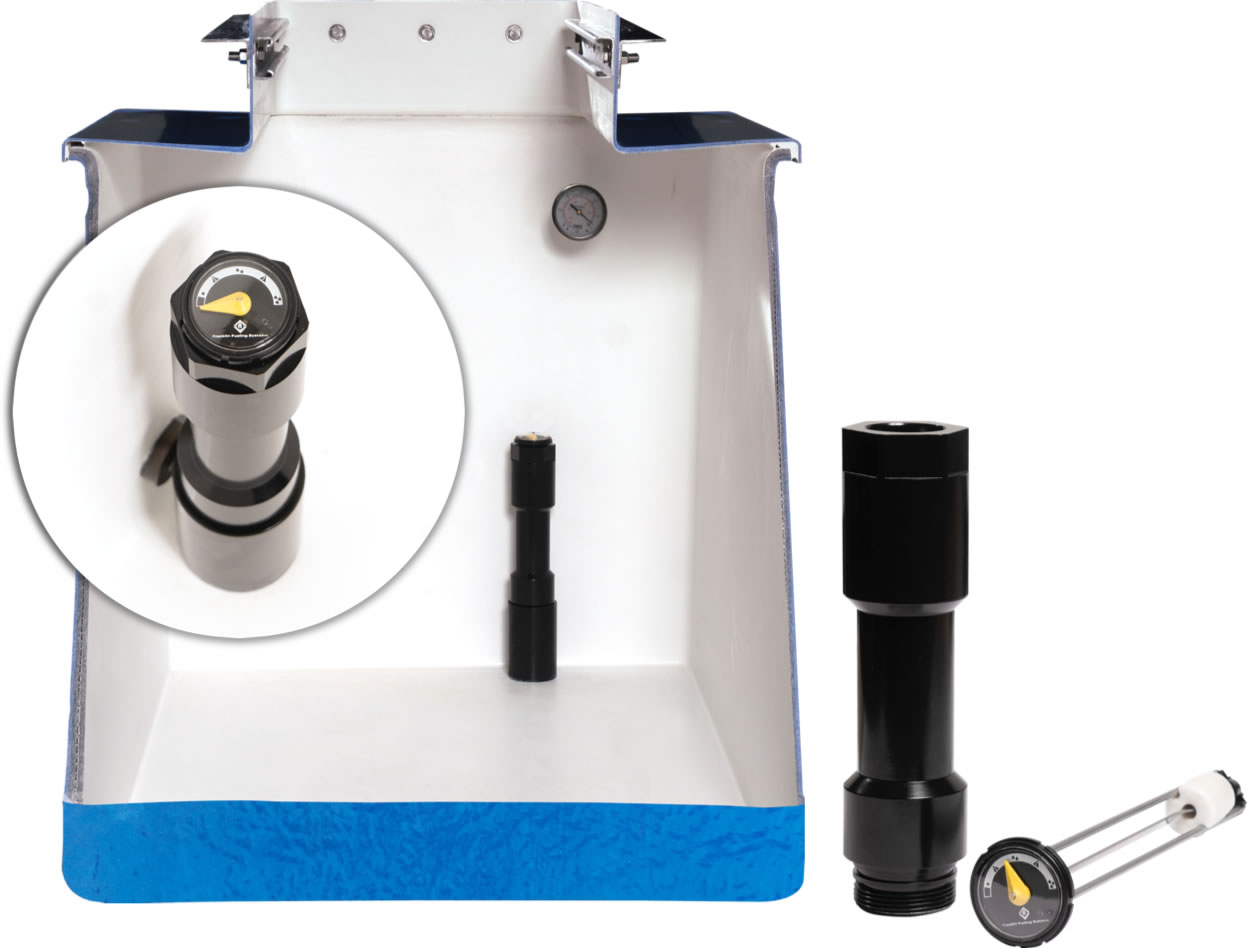

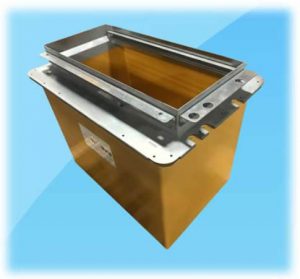

Fiberglass Tank Sumps: Watertight 2-PieceDesigned to provide maximum protection from water intrusion with a simplified installation process, the Watertight Fiberglass Tank Sump delivers easy access to tank top equipment for fast maintenance and servicing. Completing the installation is simple. The pour-in-place slurry secures the riser to the base’s integrated channel, with no messy fiberglassing required. Available without bottom or with enclosed bottom.

|

|||||||||||||||||||||||||||||||||||||||

SIMPLE INSTALLATION, WATERTIGHT PROTECTION

TECHNICAL ADVANTAGES

GAME-CHANGING WATERTIGHT LIDTo achieve the highest level of protection against water intrusion and ultimate ease-of-use, the watertight fiberglass tank sump incorporates the best features of a manway into the tank sump lid.

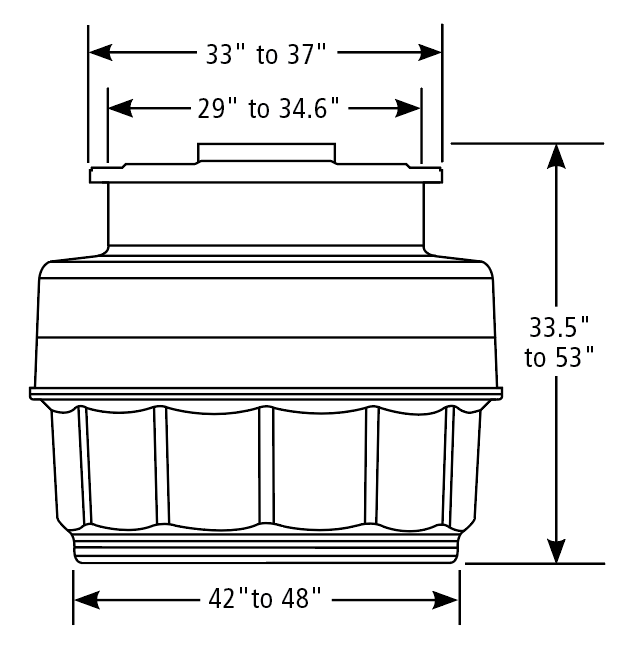

SIMPLIFIED INSTALLATIONWatertight tank sumps are available at a standard height of 60” and adjustable in the field down to 34” to accommodate shallow-buried tanks.

MAINTENANCE MADE EASYThe lightweight injection molded HDPE lid weighs only 21 pounds, making it easy to remove and maneuver during maintenance or service.

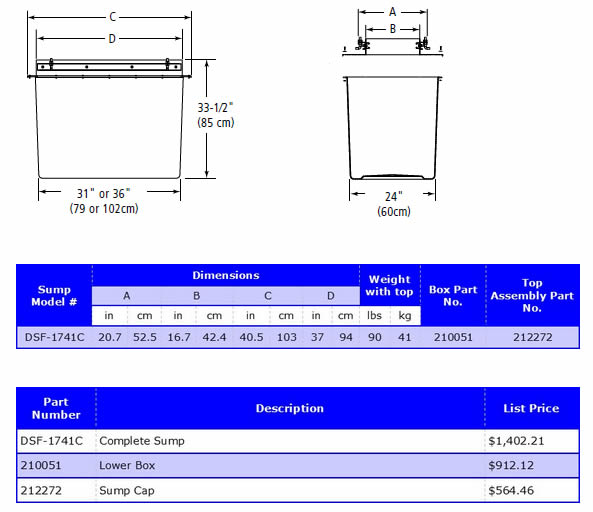

Components

1. Lid with side-sealing gasket 2. Riser 3. Base 4. Lid latches 5. Fill channel 6. Collar with open bottom 7. Retractable handles 8. Vapor pressure vent 42” Watertight Fiberglass Tank Sump Dimensions

48” Watertight Fiberglass Tank Sump Dimensions

Watertight Fiberglass Tank Sump Installation Tools & AccessoriesPour-In-Place Slurry Kit

∎ One kit required per tank sump. Collar Mount Seam Kit

∎ One kit required per tank sump. Installation Accessories Kit

Replacement Latches

|

|

|

|

|

|

|

|

|

|

If you have any questions about Franklin Fueling Systems APT watertight fiberglass tank sumps or would like to receive a quote, please feel free to contact us at 1-800-451-4021 or Email Us with any further questions or inquiries.

The John W. Kennedy Company appreciates your business and continued support!

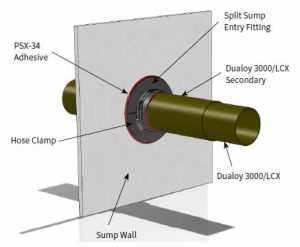

NOV Fiber Glass Systems has announced their product line will feature a new Split Sump Entry Fitting (SSEF). These fittings, designed to be used with 3/4″ and 1″ conduit as well as 2″-4″ Red Thread IIA and Dualoy fiberglass pipe. Comprised of two halves bonded together with PSX-34 adhesive, the SSEF is made from the same compression molded fiberglass as other UL971-listed fittings. The design of this fitting is made for easy installation and retrofitting.

NOV Fiber Glass Systems has announced their product line will feature a new Split Sump Entry Fitting (SSEF). These fittings, designed to be used with 3/4″ and 1″ conduit as well as 2″-4″ Red Thread IIA and Dualoy fiberglass pipe. Comprised of two halves bonded together with PSX-34 adhesive, the SSEF is made from the same compression molded fiberglass as other UL971-listed fittings. The design of this fitting is made for easy installation and retrofitting.