…Or everything you ever wanted to know about a fuel system but were afraid to ask…

…Or everything you ever wanted to know about a fuel system but were afraid to ask…

Franklin Fueling Systems provides a rudimentary understanding of a fuel system and takes the complex orchestration of the entire system to break it down to the basics in this nicely animated video. This is a great learning tool to put in front of new people entering the industry to quickly get them up to speed on what happens underground or for those curious to learn and understand more about the entire system; whether they sell, install or service equipment or own / work at a gas station.

And after you check out the video, be sure to check out the various links below to Franklin Fueling products found in the JWK Webstore as well as the great resources at FranklinFueling.com.

Be sure to check out our ever-expanding product offerings and great deals from Franklin Fueling’s many brands found in our webstore.

|

|

|

|

|

|

|

|

|

The John W. Kennedy Company appreciates your business and continued support!

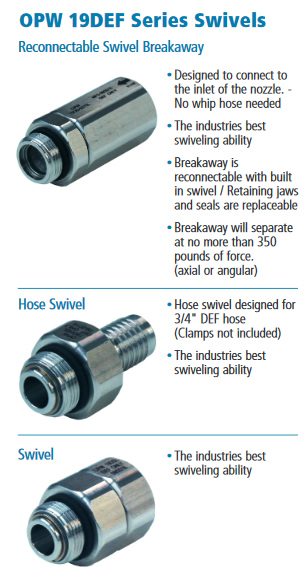

To coincide with the release of their Industrial 19DEF nozzles, OPW is releasing a series of compatible DEF breakaways and swivels. The 19D series (the 19DB Reconnectable Swivel Breakaway, 19DHS Barbed Hose Swivel, and 19DS Single Plane Hose Swivel) can be used with either the NPT or BSPP threaded 19DEF nozzles. The 19D series breakaways and swivels are manufactured entirely out of stainless steel and other ISO22241 materials.

To coincide with the release of their Industrial 19DEF nozzles, OPW is releasing a series of compatible DEF breakaways and swivels. The 19D series (the 19DB Reconnectable Swivel Breakaway, 19DHS Barbed Hose Swivel, and 19DS Single Plane Hose Swivel) can be used with either the NPT or BSPP threaded 19DEF nozzles. The 19D series breakaways and swivels are manufactured entirely out of stainless steel and other ISO22241 materials.