Gas station fuel dispensers, the unsung heroes of our transportation infrastructure, play a crucial role in ensuring vehicles stay fueled up and ready to hit the road. However, these dispensers require regular maintenance to operate efficiently like any machinery.

In this blog, we’ll explore some essential tips for maintaining and optimizing gas station fuel dispensers.

Regular Inspection and Maintenance

Just like your car needs regular oil changes and tune-ups, gas station fuel dispensers require routine inspection and maintenance to function smoothly. Neglecting these tasks can lead to minimal efficiency and even safety hazards. Here are some key areas to focus on during routine maintenance:

- Nozzle inspection: Start by visually inspecting the fuel nozzles for any signs of wear and tear like cracks, leaks, or damaged seals. Replace any damaged components promptly to prevent fuel leaks or spills, which can pose environmental risks and safety hazards.

- Calibration checks: Accurate calibration is essential for ensuring customers receive the correct amount of fuel they pay for. Periodically calibrate the dispensers to verify their accuracy and compliance with regulatory standards.

- Filtration system maintenance: The filtration system plays a crucial role in preventing contaminants from entering the fuel dispensing system and vehicles’ fuel tanks. Regularly inspect and clean fuel filters to ensure optimal filtration efficiency.

Optimize Dispensing Speed and Accuracy

Efficiency is the name of the game in the fast-paced world of gas station operations. Optimizing dispensing speed and accuracy not only enhances customer satisfaction but also maximizes throughput and revenue. Here are some strategies for achieving optimal performance:

- Upgrade to high-speed dispensers: Consider investing in high-speed fuel dispensers equipped with advanced technology to minimize wait times. These modern dispensers feature faster flow rates and improved accuracy, enhancing the overall fueling experience for customers.

- Implement automatic shut-off systems: Automatic shut-off systems help prevent overfilling and spills by cutting off the fuel flow when the tank reaches its predetermined capacity. Installing these systems not only improves safety but also minimizes fuel wastage and reduces the risk of environmental contamination.

- Utilize Remote Monitoring: Embrace digital solutions that enable remote monitoring and management of fuel dispensers, allowing operators to track key performance indicators, detect issues in real time, and schedule maintenance tasks more efficiently.

Ensure Compliance with Regulatory Standards

Compliance with regulatory standards is non-negotiable when it comes to operating gas station fuel dispensers. Failure to adhere to these standards can result in fines, legal liabilities, and reputational damage.

Find out more about federal and local regulations governing fuel dispensing operations, including safety standards and metrology regulations. Regularly review and update your compliance protocols to ensure alignment with the latest regulatory developments.

Perform regular inspections and audits to verify compliance with regulatory standards and identify any areas of non-compliance. Address any issues promptly and implement corrective measures to mitigate risks and ensure ongoing compliance.

Connect With Us To Invest In Top-Quality Fuel Dispensers

For all your gas station supply needs, consider connecting with John W. Kennedy Company. Our gas station supply store offers a comprehensive range of gas station accessories supplies and service station supplies to meet your operational requirements. With our commitment to excellence and expertise in the distribution of petroleum equipment, we ensure you have everything you need to keep your gas station running smoothly.

So, what are you waiting for? Get in touch with us for more details.

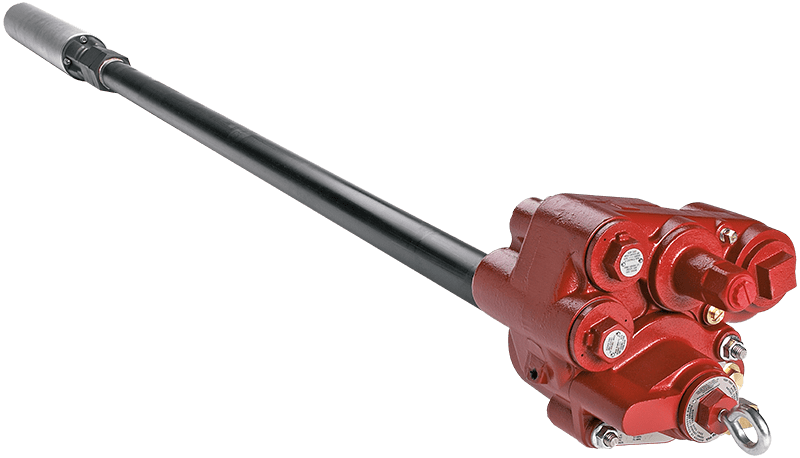

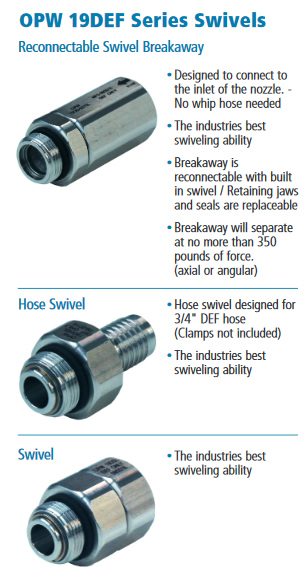

To coincide with the release of their Industrial 19DEF nozzles, OPW is releasing a series of compatible DEF breakaways and swivels. The 19D series (the 19DB Reconnectable Swivel Breakaway, 19DHS Barbed Hose Swivel, and 19DS Single Plane Hose Swivel) can be used with either the NPT or BSPP threaded 19DEF nozzles. The 19D series breakaways and swivels are manufactured entirely out of stainless steel and other ISO22241 materials.

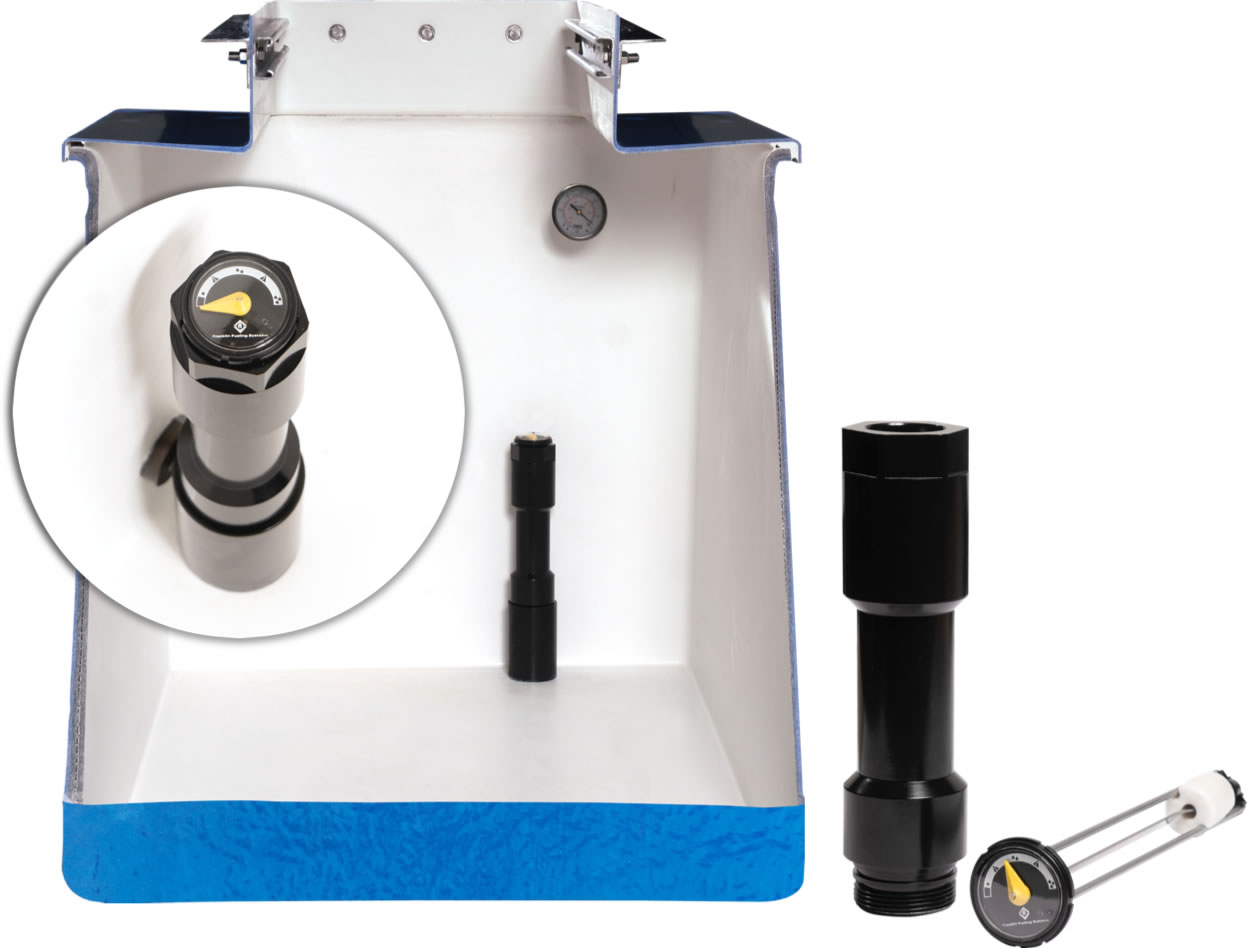

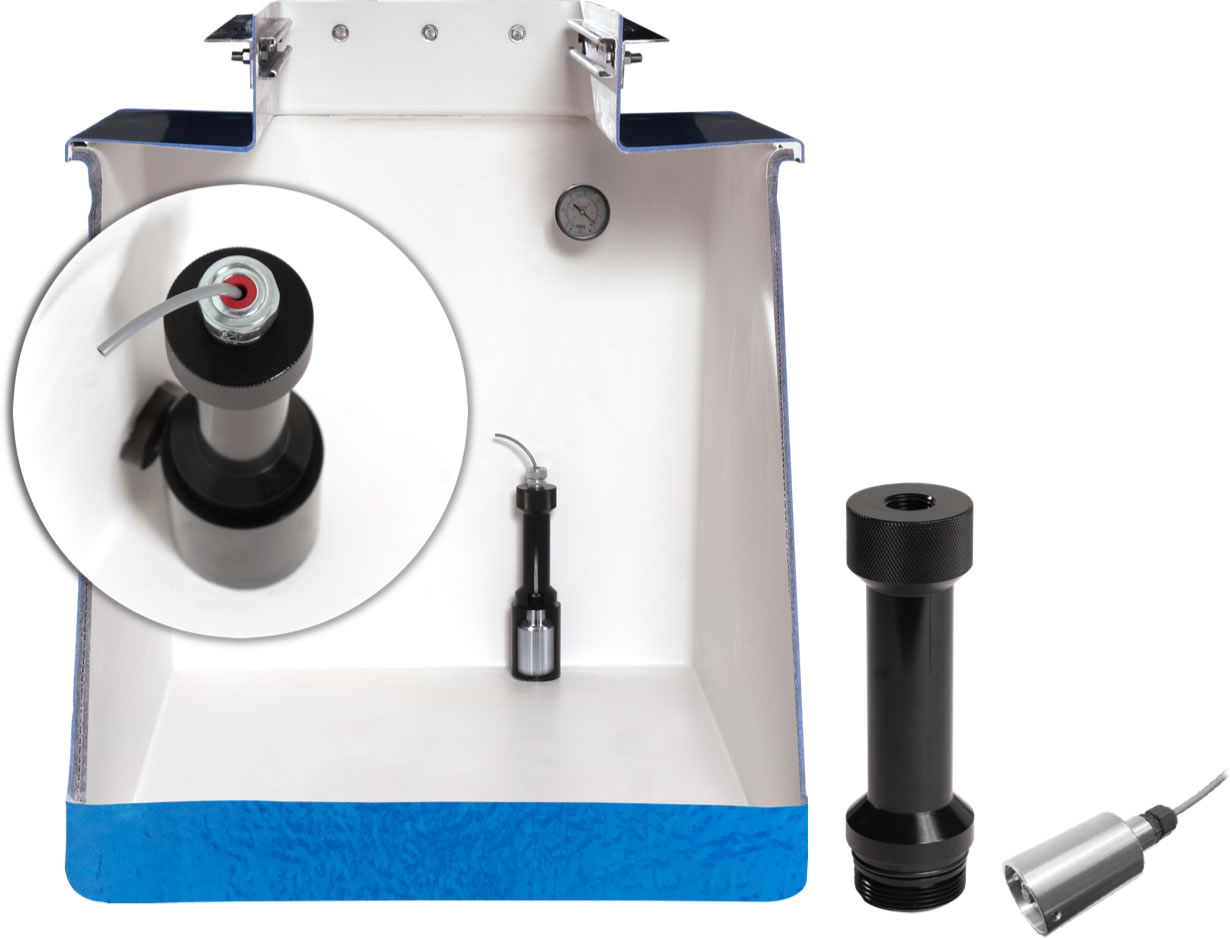

To coincide with the release of their Industrial 19DEF nozzles, OPW is releasing a series of compatible DEF breakaways and swivels. The 19D series (the 19DB Reconnectable Swivel Breakaway, 19DHS Barbed Hose Swivel, and 19DS Single Plane Hose Swivel) can be used with either the NPT or BSPP threaded 19DEF nozzles. The 19D series breakaways and swivels are manufactured entirely out of stainless steel and other ISO22241 materials. The OPW DEF Mis-Filling Prevention Device is now available for Truck Stops and Convenience Stores. There are countless vehicles not equipped with MFPD technology, and this device is required when magnetic DEF Nozzles are used. Provide your customer peace of mind by stocking the MFPD in your retail outlet.

The OPW DEF Mis-Filling Prevention Device is now available for Truck Stops and Convenience Stores. There are countless vehicles not equipped with MFPD technology, and this device is required when magnetic DEF Nozzles are used. Provide your customer peace of mind by stocking the MFPD in your retail outlet.