PRODUCT LAUNCH:

NEW CARBON SERIES™ FIBERGLASS DISPENSER SUMPS

Franklin Fueling Systems is pleased to announce the launch of our Carbon Series™ single wall and double wall fiberglass dispenser sumps. Check out the new and model-specific highlights of this new family of dispenser sumps.

- Economically Priced

- Available in models compatible with both Gilbarco Encore® dispensers and Wayne Ovation® dispensers.

- Dispenser top and top frame are joined together prior to leaving the factory saving field installation time

- New Light Resin Transfer Molding (Light RTM) technology used to manufacture single wall sumps gives them consistent wall thickness throughout the entire assembly for superior rigidity as well as an extremely smooth surface to facilitate watertight entry boot installation.

- Gilbarco Encore® DEF sump option available with two-sump design.

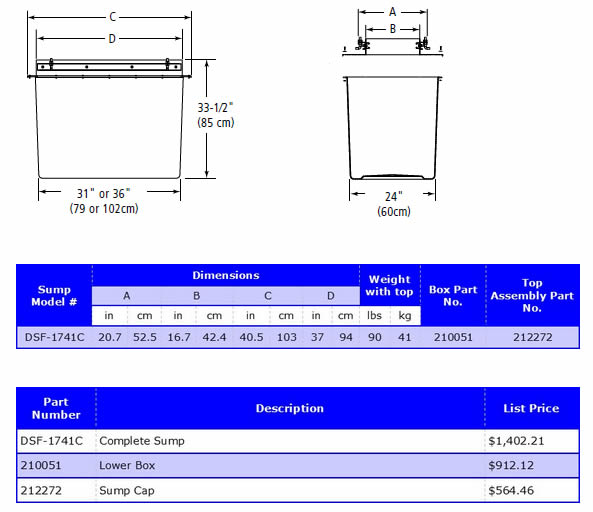

| 602375001: Carbon Series™ single wall fiberglass sump for Gilbarco Encore® bow-tie end dispenser models (requires SBK-3 stabilizer bar kit, sold separately) |

602377001: Carbon Series™ single wall fiberglass sump for Gilbarco Encore® bow-tie end dispenser models with banded DEF polyethylene sump (requires SBK-3 stabilizer bar kit, sold separately) |

602381001: Carbon Series™ single wall fiberglass sump for Wayne Ovation® dispenser models (requires SBK-25 stabilizer bar kit, sold separately) |

Note: one stabilizer bar kit per shear valve is required. Stabilizer bar kits sold separately.

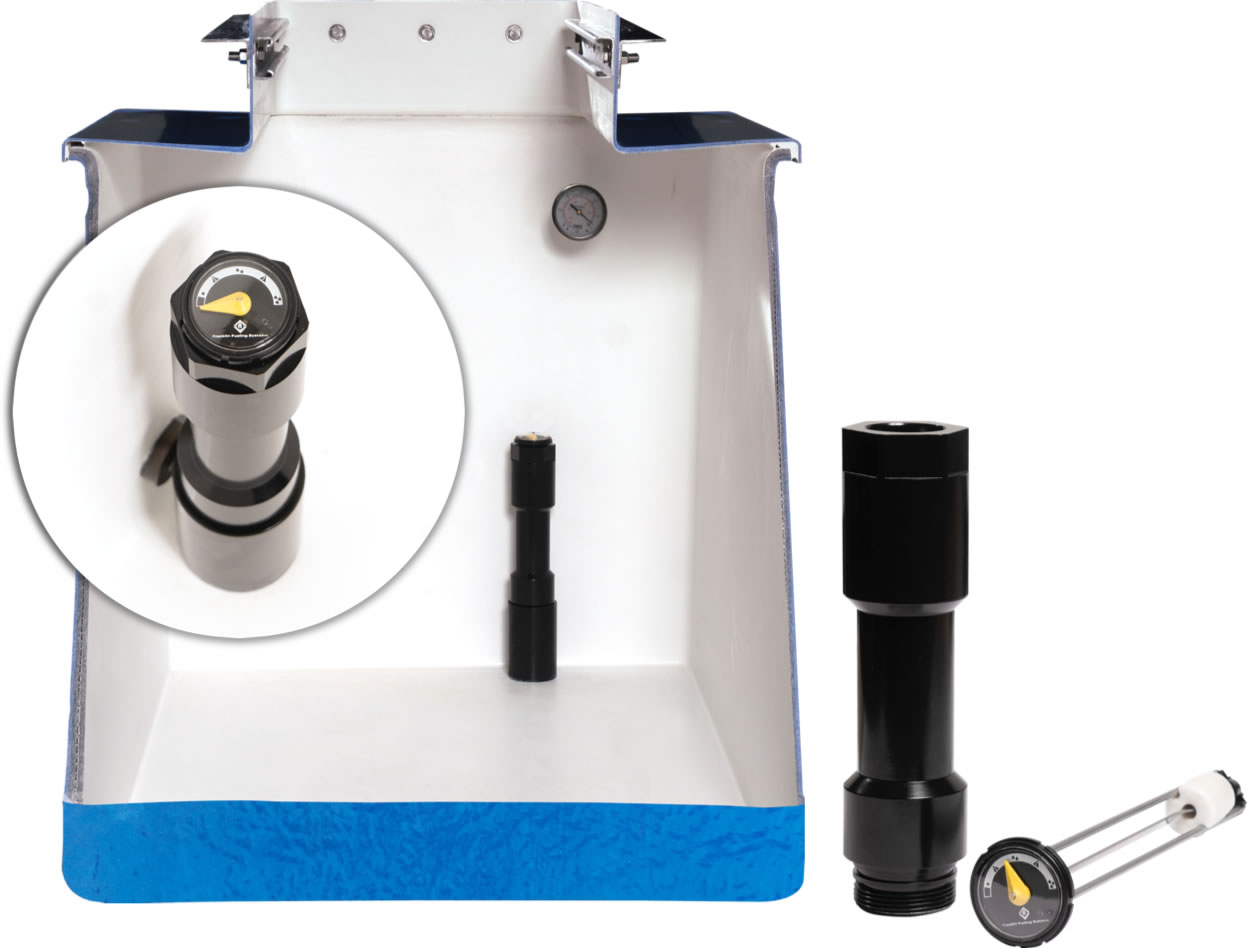

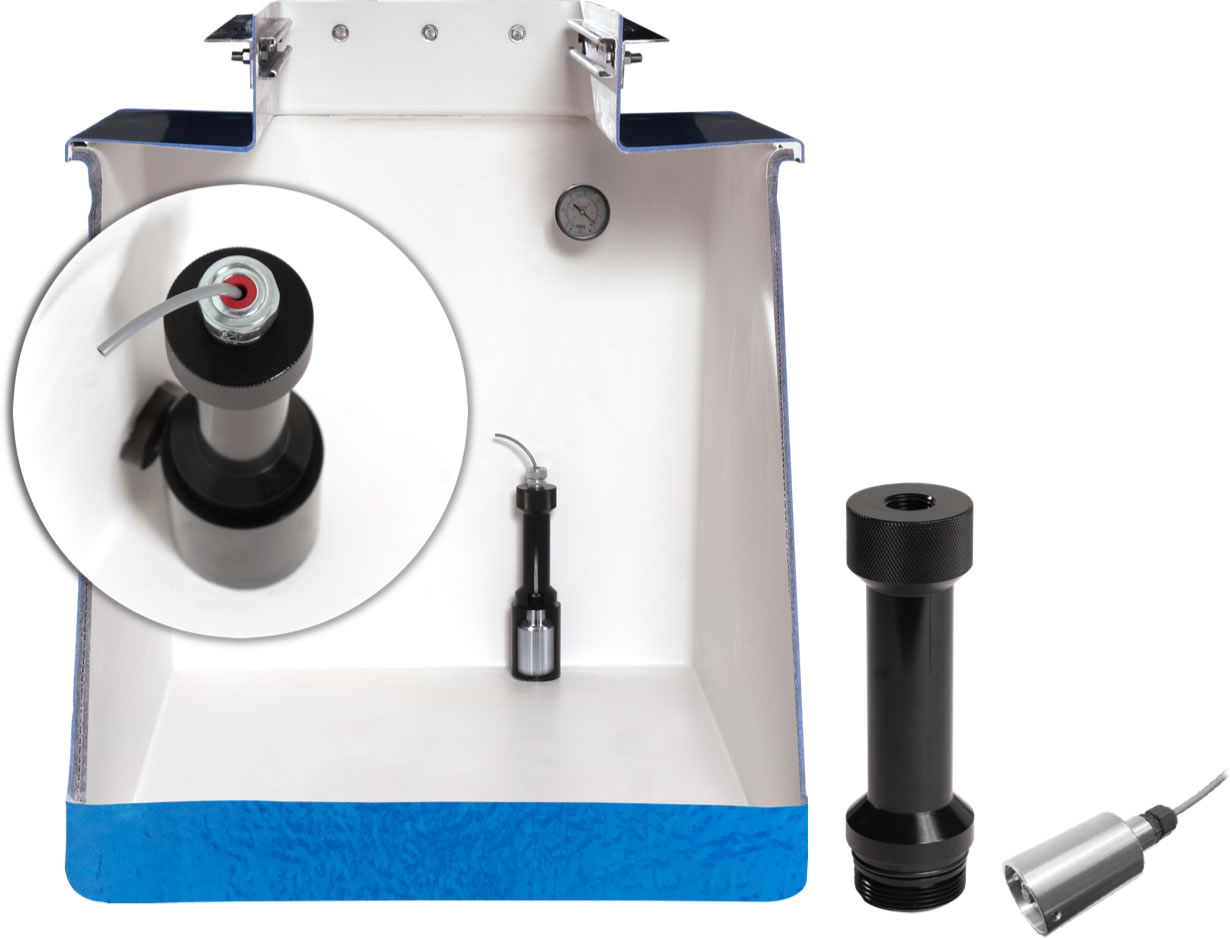

- Can be ordered with a pre-installed port for either electronic, mechanical, or hydrostatic continuous monitoring of the double wall interstitial space.

- Included vacuum gauge ships under airtight vacuum to ensure the integrity of the interstitial space during shipment to the jobs site.

| 602383001: Carbon Series™ double wall fiberglass sump for Gilbarco Encore® bow-tie end dispenser models with vacuum port (requires SBK-3 stabilizer bar kit, sold separately |

602383401: Carbon Series™ double wall fiberglass sump for Gilbarco Encore® bow-tie end dispenser models with vacuum port and port for interstitial monitoring* (requires SBK-3 stabilizer bar kit, sold separately |

602385001: Carbon Series™ double wall fiberglass sump for Wayne Ovation® dispenser models with vacuum port (requires SBK-25 stabilizer bar kit, sold separately) |

602385401: Carbon Series™ double wall fiberglass sump for Wayne Ovation® dispenser models with vacuum port and port for interstitial monitoring* (requires SBK-25 stabilizer bar kit, sold separately) |

Note: one stabilizer bar kit per shear valve is required. Stabilizer bar kits sold separately.

*Interstitial monitoring accessory must be ordered separately.

Carbon Series Double Wall Monitoring Options:

| Mechanical Monitoring | Electronic Monitoring | Hydrostatic Continuous Monitoring |

|

|

|

Franklin Fueling will be introducing the Carbon Series dispenser sumps at the John W. Kennedy Company Forging Relationships Trade Show on March 27 & 28, 2019. Please stop by the Franklin booth to learn more!

The John W. Kennedy Company appreciates your business and continued support!