This is Veeder-Root’s fourth article in their series on what actually happens when you fill up at a gas station. Read the others here:

Behind the Scenes of Filling Up:

1. How Does it Work?

2. Gaining Approval and Getting Started

3. How does the fuel actually get to the nozzle?

.

With so much fuel passing through a gas station’s fueling system, how do they ensure that fuel isn’t leaking?

For decades now, the Environmental Protection Agency has enforced regulations that require gas stations to prove they aren’t leaking fuel into the ground or the water supply, and there are a number of ways the gas station can meet the requirements.

But beyond the regulations, fuel costs money – it’s the single most expensive inventory item for gas stations – and leaks or other fuel losses are costly!

Managing Compliance

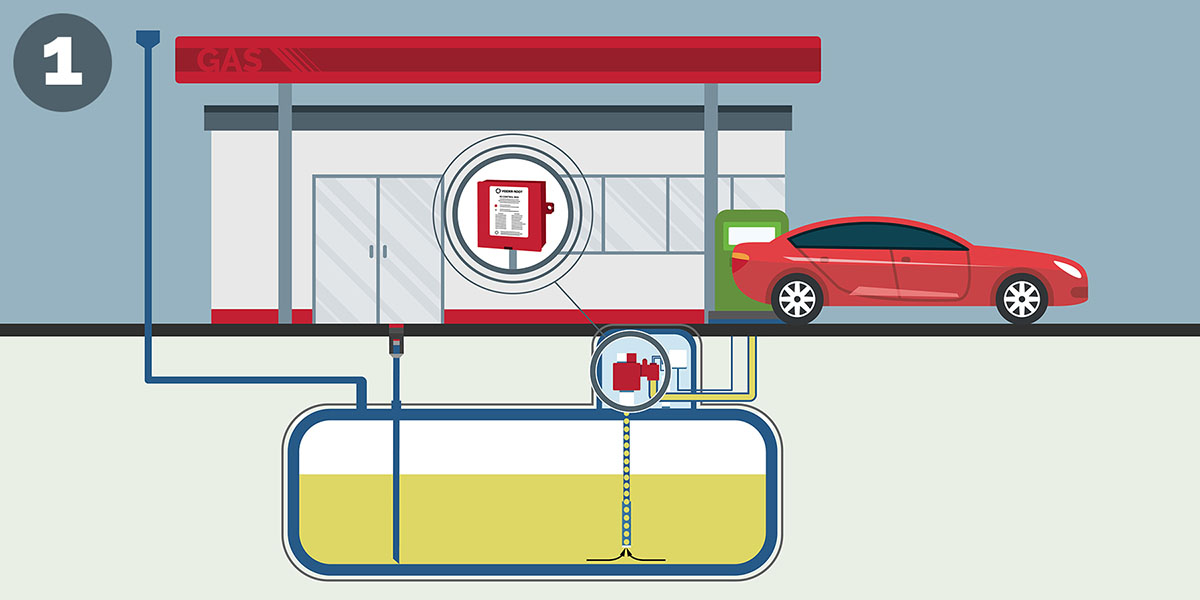

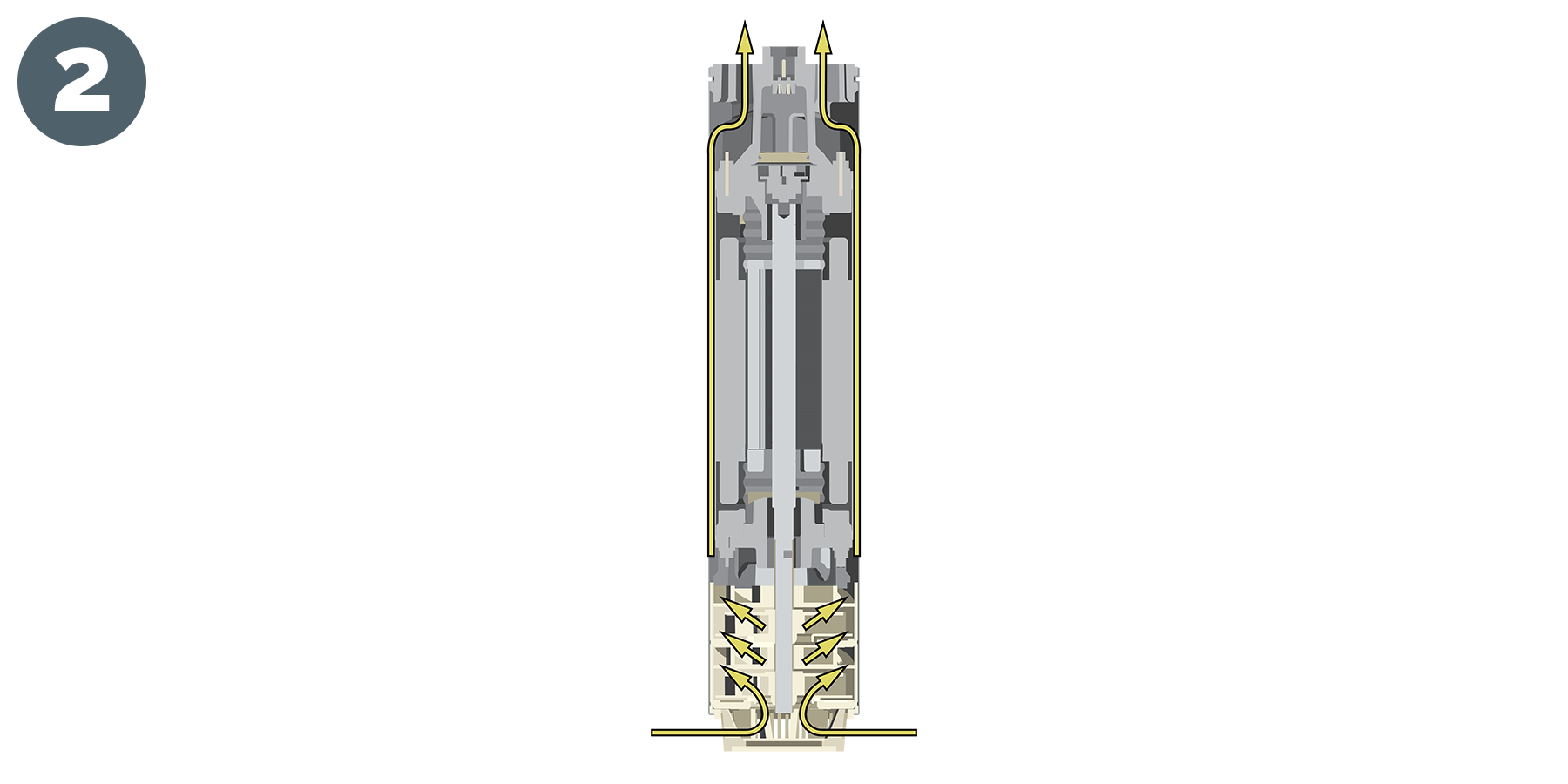

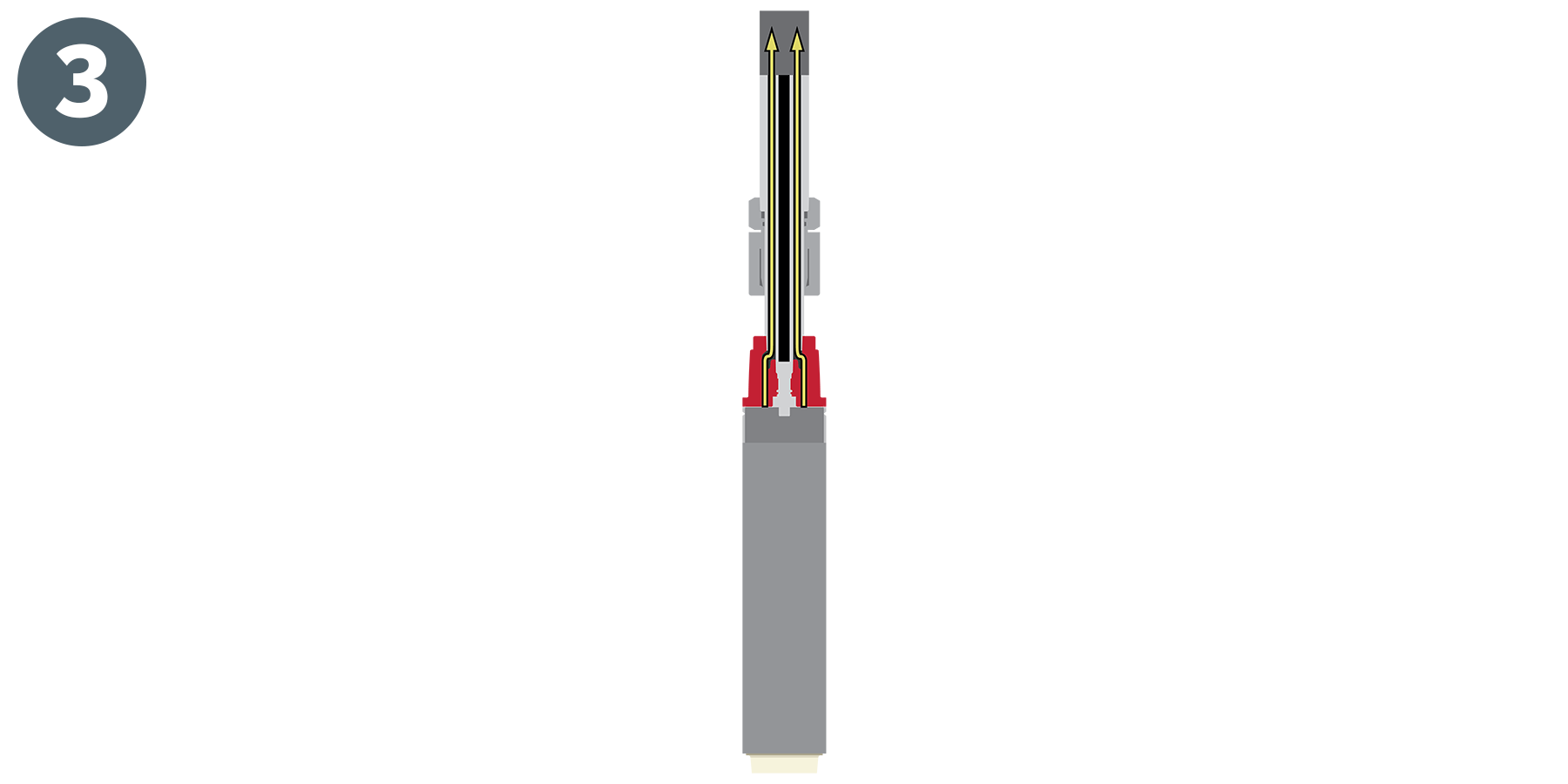

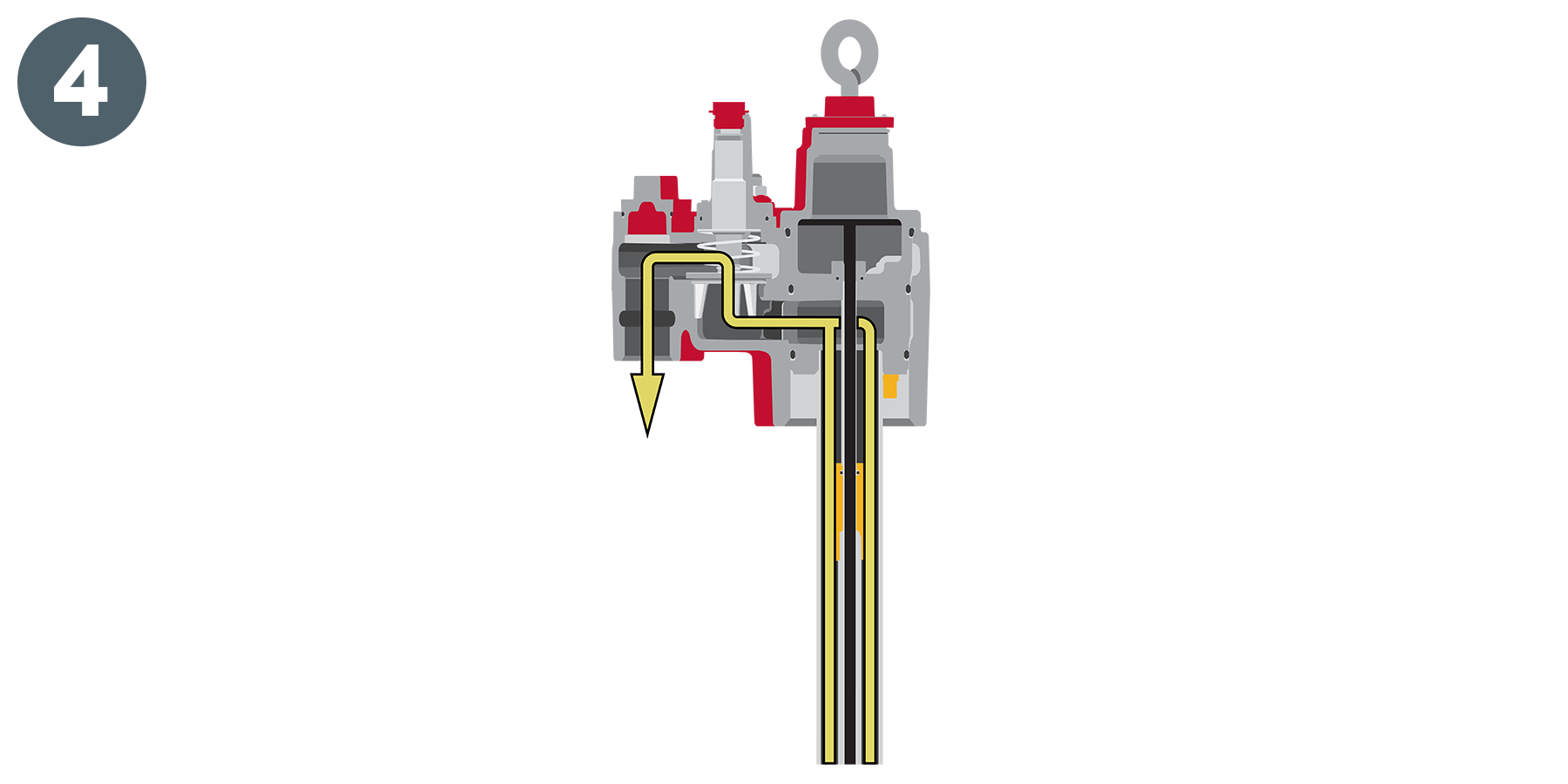

Once you’re done filling up, there is an entire monitoring system at the gas station that tests the fuel lines for any potential leaks and monitors important spaces around the site to ensure they’re dry. This system is called an automatic tank gauging system which includes a console, like the TLS-450PLUS ATG, series of sensors throughout the gas station, and probes in the underground fuel tanks.

The automatic tank gauge system has many functions at a gas station, but at its core it provides the owner and store operator with reports that prove the site isn’t leaking fuel and provides the fuel inventory data needed to run the station. These reports are provided to EPA inspectors to ensure gas stations are complying with the regulations.

Fixing Issues Immediately

It’s important to have the appropriate reports, but leaks must be addressed in real time, and that is where the ATG console is also working like a security system for the fuel site.

When an issue is detected in the fueling system, the TLS-450PLUS ATG records a condition result and generates an audible and visual alarm for the store operator. Employees at the site can then follow their protocol for addressing the issue.

The guiding principle is ensuring that the gas station is safe for customers and meeting regulations.

What’s Next?

Next week, we’re discussing how the TLS-450PLUS ATG gives C-Store owners and operators the business data they need to correctly manage their inventory.

You can find more information on every step of the process here.

If you have any questions or would like to purchase Veeder-Root and Red Jacket Products, visit us online at www.johnwkennedyco.com or call us at 1.800.451.4021.

The John W. Kennedy Company appreciates your business and continued support!