SAFETY ALERT

SAFETY ALERT

Between January 1, 2017 and January 10, 2018, Graco 110225 ball valves were not manufactured correctly by Graco’s supplier!

The incorrect valves do not have a vent hole, and as a result will not vent pressure when turned to the closed position. Air pressure can then become trapped downstream of the valve potentially causing serious injury due to unexpected movement of equipment.

Here is a a list of affected products:

| Part Number | Description | Part Number | Description |

| 110225 | VALVE, VENTED, TWO-WAY, ½ | 246669 | SYSTEM, WASTE OIL PUMP TRENCH |

| 244680 | SYSTEM, BULK ANTIFREEZE/WWS | 244648 | SYSTEM, BULK GREASE |

| 244847 | SYSTEM, BULK OIL | 246672 | SYSTEM, WWS PUMP |

| 244628 | SYSTEM, BULK OIL | 244679 | SYSTEM, BULK ANTI-FREEZE/WWS |

| 244846 | SYSTEM, BULK OIL | 246657 | SYSTEM, AIR DROP |

| 246659 | SYSTEM, AIR DROP & TIRE CHANGER | 244646 | SYSTEM, BULK GREASE |

| 244641 | SYSTEM, BULK GREASE |

Your safety is Graco’s and our highest priority. All incorrect valves in inventory and in use must be removed, quarantined and replaced.

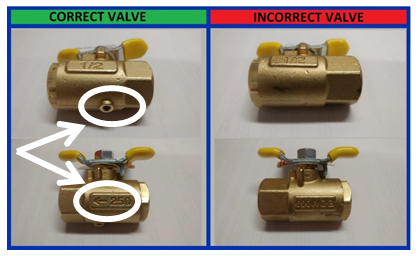

The correct valve has a vent hole and is marked with a directional arrow and the number 250.

The correct valve has a vent hole and is marked with a directional arrow and the number 250.

The incorrect valve does not have a vent hole and the markings are different.

If you have identified that you purchased any of the affected valves and/or equipment packages between 1/1/2017 to 1/10/2018, here are the required actions to follow:

- Inspect the valves and packages for the incorrect valve

- You must REMOVE or QUARANTINE the incorrect valve

- If you can not remove the valve from use immediately, it is extremely critical that you find a method to relieve trapped air pressure before cleaning, inspecting or servicing the equipment

- Contact us at 1.800.451-4021 to replace the incorrect valves

- A warranty claim will be created

- the incorrect valves must be returned to Graco to receive credit for the incorrect valves

- UPDATE as of 2/8/2018 – Graco WILL reimburse for labor on a case by case basis!

We apologize for any inconvenience this may cause. If you have any further questions or require assistance, please call us at 1.800.451.4021.

The John W. Kennedy Company appreciates your business and continued support!

And while the contractors learn first hand from the manufacturer how the product should look when it shows up on site and how best to go about installations, they also share their trials and tribulations of the realities on the job site. As Micah Nelson spoke to a packed house, reviewing Bravo off-the-shelf products and those assemblies they build specifically for Cumberland Farms during the half day event, the exchange between presenter and attendees brought to light details and issues new to both sides. There were also discussions about the direction the future holds. This is exactly what drove the concept for the Best Practices seminar series.

And while the contractors learn first hand from the manufacturer how the product should look when it shows up on site and how best to go about installations, they also share their trials and tribulations of the realities on the job site. As Micah Nelson spoke to a packed house, reviewing Bravo off-the-shelf products and those assemblies they build specifically for Cumberland Farms during the half day event, the exchange between presenter and attendees brought to light details and issues new to both sides. There were also discussions about the direction the future holds. This is exactly what drove the concept for the Best Practices seminar series.