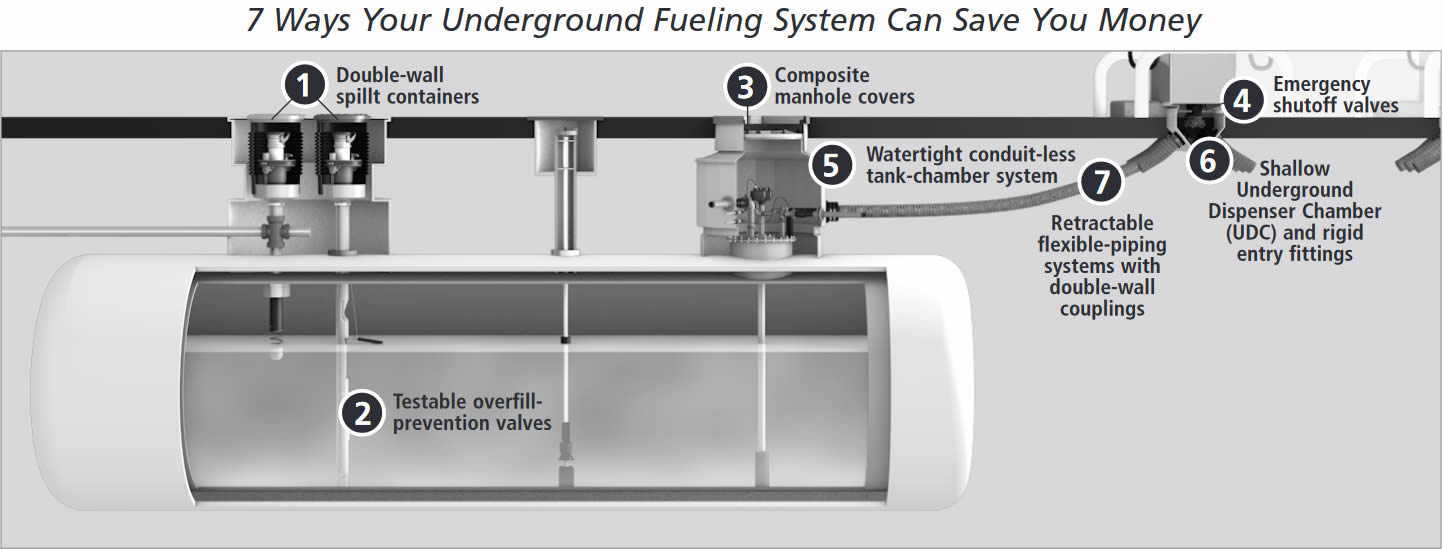

Our friends at OPW would just like to kindly remind everyone that the EPA’s new Environmental Testing Regulations go into full effect on October 13, 2018, and OPW has a full line of products that are compatible with the 4 major regulatory requirements for new and existing Underground Storage Tank (UST) systems.

Our friends at OPW would just like to kindly remind everyone that the EPA’s new Environmental Testing Regulations go into full effect on October 13, 2018, and OPW has a full line of products that are compatible with the 4 major regulatory requirements for new and existing Underground Storage Tank (UST) systems.

Watch the video below and learn more at opwglobal.com/epa-regulations!

Check out our blog post from August 2018, Are You Ready?? The Cost of Non-Compliance: You Can’t Afford It, containing OPW’s infographic that covers the history of UST Regulations.

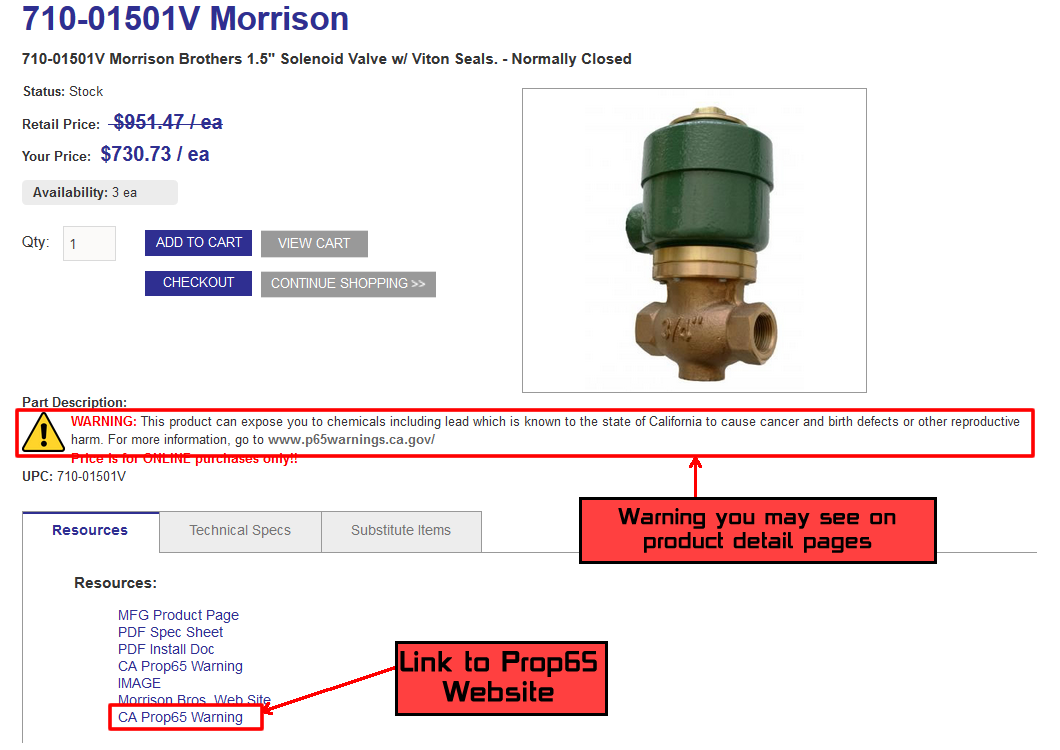

You can find many of OPW’s great products in our web store and if you don’t find what you are looking for there or have any questions, feel free to contact us at 1.800.238.1225.

Click on the logos below to explore OPW products online:

The John W. Kennedy Company appreciates your business and continued support!