Software Release Version 10.B

Software Release Version 10.B

TLS-450PLUS and TLS4 Series Consoles

Purpose

This document announces the release of version 10.B software for the TLS-450PLUS and TLS4 series consoles.

Performance Enhancements

Intelligent Pump Control Reports

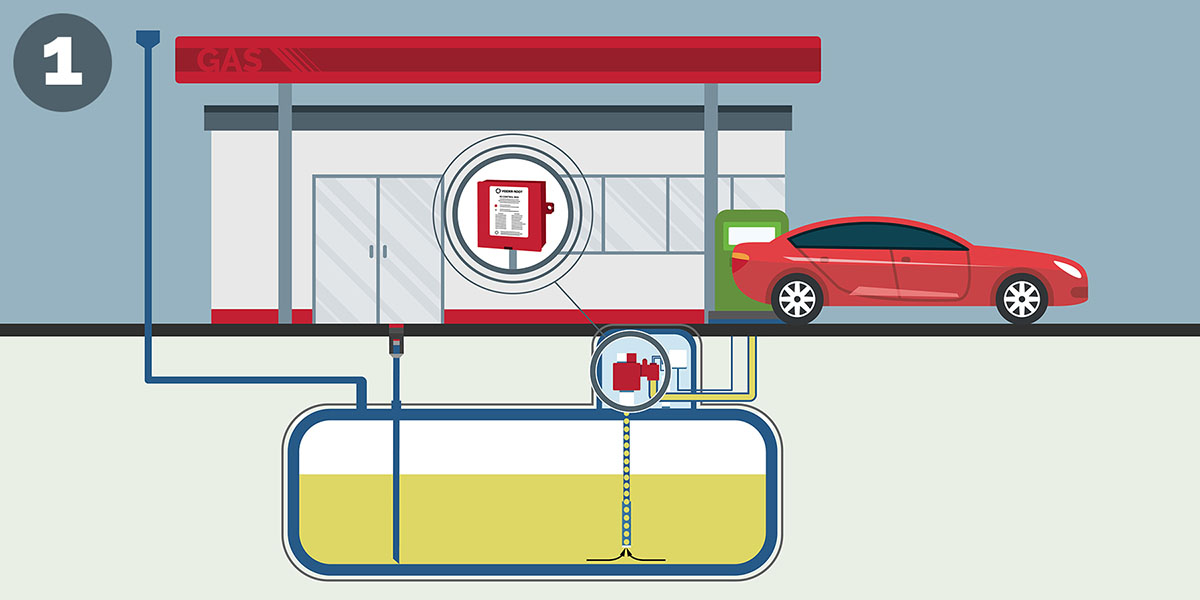

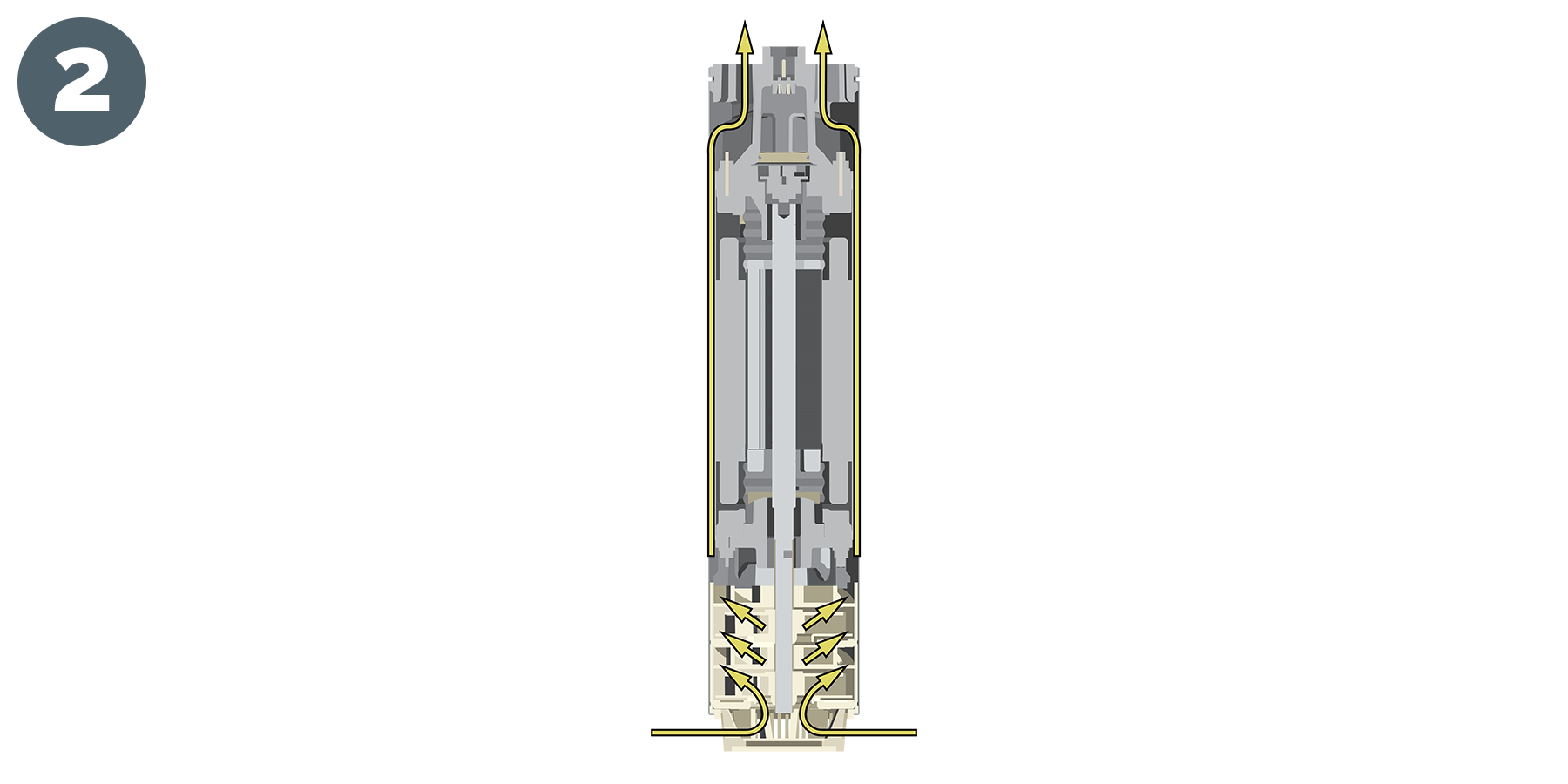

• Advanced Diagnostics Reporting for Intelligent Pump Control (IPC) for Red Jacket STPs. IPC collects statistical data from pump controllers that includes daily run time, start count, number of help requests, faults, fault counts, time in a fault condition, min/max/average (running) voltage and amperage.

Ongoing Improvements

• Version 10.B includes miscellaneous bug fixes and updates.

Software Upgrade Kit – TLS-450PLUS, TLS4 Series Consoles

Software upgrades are always free to download on the Veeder-Root website at veeder.com/us/software-downloads.

Software upgrades can also be ordered on a USB Flash drive at no charge by ordering the software kit part number

in the table below:

| Part Number | Description | List Price |

| 0330020–744 | TLS–450PLUS, TLS4 Series Operating Software Upgrade | No Charge |

Documentation

Manual information is available at veeder.com/us/technical-document-library.

LOOKING FOR VEEDER-ROOT SYSTEMS & PARTS?

Well look no further – click on the Veeder-Root logo below to visit our web store, where we have hundreds of the most popular Veeder-Root items ready to buy in our webstore and if you can’t find it there, please contact us!

If you have any questions about this software release notification or would like to receive a quote for Veeder-Root systems and/or parts , please feel free to contact us at 1-800-451-4021 or Email Us with any further questions or inquiries.

ADD ITEMS TO TRANSACTION

ADD ITEMS TO TRANSACTION ATTENDANT AUDIO ALARM

ATTENDANT AUDIO ALARM AUTHORIZE AGE RESTRICTED ITEM

AUTHORIZE AGE RESTRICTED ITEM