Gas station canopies aren’t just aesthetic structures, they play a crucial role in providing shelter for customers, protecting fuel dispensers, and ensuring overall safety at the station. Proper canopy maintenance is essential to extend its lifespan and guarantee a safe environment for customers and employees. Continue reading this blog to learn more about canopy maintenance.

Regular Inspection and Cleaning: The Foundation of Canopy Care

Undoubtedly, gas station canopies are exposed to various elements, including weather, dust, and pollution. Over time, these factors can lead to corrosion, discoloration, and structural issues. This is why a scheduled inspection routine is necessary.

You can start by visually inspecting the canopy for any signs of damage or wear. Look for rust, dents, or any structural problems. Pay close attention to the joints and connections, as they are susceptible to wear and tear. Inspect the drainage system to ensure proper water runoff.

Regularly clean the canopy using mild detergents and a soft brush. It not only enhances its visual appeal but also prevents the buildup of grime and pollutants that can accelerate corrosion. Bird droppings should be quickly cleaned as they contain acidic substances that can damage the canopy’s surface.

Paint and Coating Maintenance: Shielding Against the Elements

Protective coatings and paint play a crucial role in protecting the canopy. Your canopy can degrade because of exposure to sunlight, rain, and other elements, which is why you must monitor the condition of the paint and coatings regularly.

If you notice peeling or fading, it’s time for a fresh coat. Repainting the canopy not only enhances its aesthetic appeal but also provides an additional layer of protection against rust. When choosing paint, opt for high-quality, weather-resistant options designed for outdoor structures. Consider applying protective coatings as they can extend the lifespan of the canopy by creating a barrier against moisture and environmental pollutants.

Lighting and Electrical System Maintenance: Ensuring Safety After Sunset

Many gas station canopies are equipped with lighting to ensure visibility and safety. Regular maintenance of the lighting and electrical systems is crucial for preventing accidents. You must inspect the wiring and other electrical components frequently.

Faulty wiring can pose a fire hazard, so addressing issues promptly is essential. Clean light fixtures regularly to remove dust and debris that can reduce illumination. Consider upgrading to energy-efficient LED lighting, which not only reduces energy costs but also provides better illumination. LED lights have a longer lifespan and require less maintenance compared to conventional lighting options.

Invest In A Brand-New Gas Station Canopy

If your gas station’s canopy is beyond repair, we recommend installing a new canopy as soon as possible. You can visit the online platform created by the John W. Kennedy Company to explore the wide range of canopies and kiosks we offer. Apart from gas station canopies, here’s a list of some of the petroleum equipment supply we deliver:

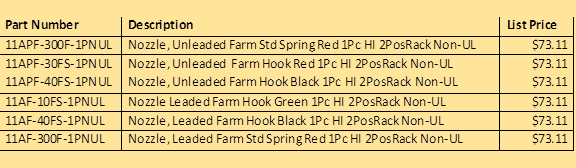

- Fuel nozzles

- POS systems

- Fuel dispensers

- LED lights

You can reach out to our team for more information.