OPW UST EVR Training Certification

OPW invites you to attend their UST EVR Training Certification class.

Description: The OPW EVR live certification course provides attendees a hand’s on opportunity to install and service all of the OPW UST EVR Phase One System Components listed on the California Air Resources Board (CARB) Executive Order. Attendees will use the tools provided in class while performing basic installation and routine maintenance of phase one components. There is no experience necessary and the class is free. There will be an open book test at the conclusion of the class and with a passing grade you will receive a 2 year certification.

When: Wednesday, December 12, 2018

Where: Hilton Garden Inn – 800 Hall of Fame Ave. – Springfield, MA 01105

IMPORTANT: Please contact us at 1.800.451.4021 or email us here ASAP to reserve a spot with the attendee name, company name & email address. Please note: all (3) bits of information are needed in order to officially register the attendee for the training class.

Enrollment will be on a first come first serve basis. If registration is low there is a possibility that training sessions may be cancelled.

The John W. Kennedy Company appreciates your business and continued support!

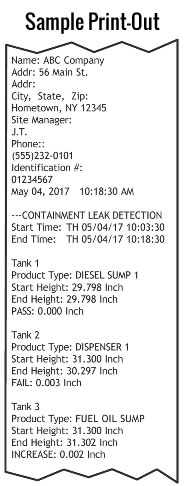

Omntec offers the CLD Series portable containment sump tester, available in 3, 4, 6 , and 8 probe versions.

Omntec offers the CLD Series portable containment sump tester, available in 3, 4, 6 , and 8 probe versions.

Attached is an Enforcement Discretion Directive, effective immediately, allowing the installation of Stage I enhanced vapor recovery (EVR) systems and components that are contained in California Air Resources Board (CARB) Orders issued since January 2, 2015 prior to the effective date of revisions to 310 CMR 7.24(3).

Attached is an Enforcement Discretion Directive, effective immediately, allowing the installation of Stage I enhanced vapor recovery (EVR) systems and components that are contained in California Air Resources Board (CARB) Orders issued since January 2, 2015 prior to the effective date of revisions to 310 CMR 7.24(3).

The following has been reproduced from a Morrison Brothers email blast from the desk of Rick Zillig, Manager QCCS

The following has been reproduced from a Morrison Brothers email blast from the desk of Rick Zillig, Manager QCCS