OPW Has Releases 3-Part Video Series; “Retail Fueling Basics (101-Level Training)”

OPW’s own industry veteran, Edward Kammerer

guides you through this video series meant for both

industry veterans and those new to retail fueling

equipment and environments.

You can also download the workbook

You can also download the workbook

to go along with the videos here.

RETAIL FUELING BASICS: PART I

In Part I of this series, Ed will discuss underground storage tanks, overfill & spill protection, coaxial, dual point- and multi-port fuel drops and Stage I vapor recovery

RETAIL FUELING BASICS: PART II

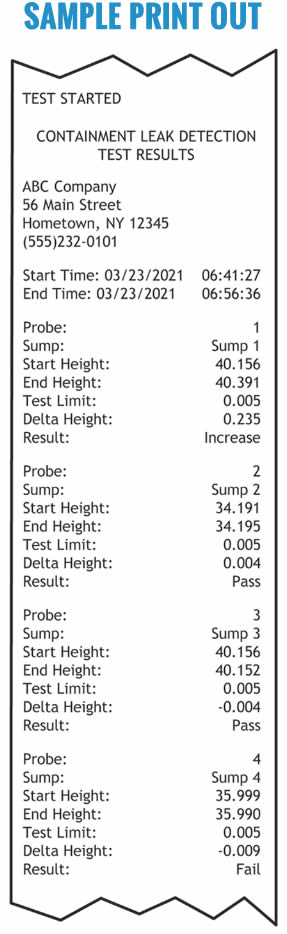

In Part II of this series, Ed walks you through how fuel moves from the UST to the fueling island. He will introduce you to piping, entry fittings and double wall containment systems.

RETAIL FUELING BASICS: PART III

In Part III of this series, Ed discusses what’s at the dispenser; containment sumps, shear valves hanging hardware and other equipment.

You can find many other great OPW products in our webstore.

|

||

|

|

|

|

And if you don’t find the OPW products you are looking for or have further questions about any product, feel free to contact us at 1.800.451.4021 or email us!

The John W. Kennedy Company appreciates your business and continued support!

CLICK HERE to check out ALL Omntec Monitor Systems we currently have in our web store

CLICK HERE to check out ALL Omntec Monitor Systems we currently have in our web store

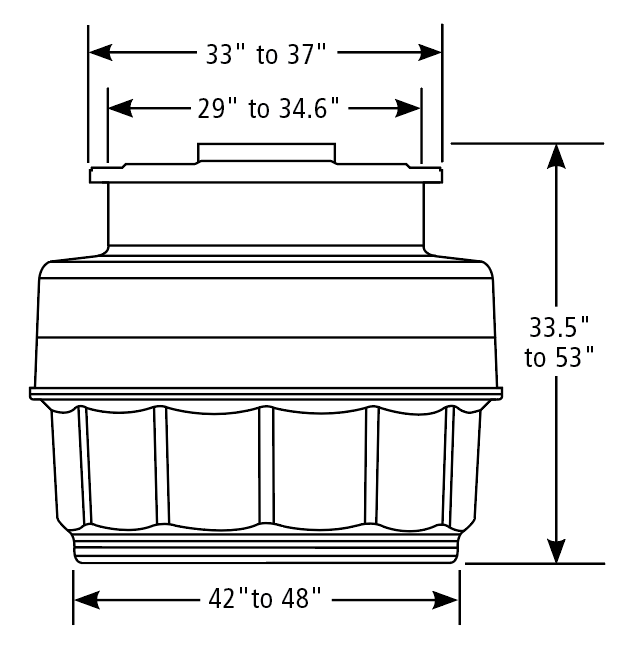

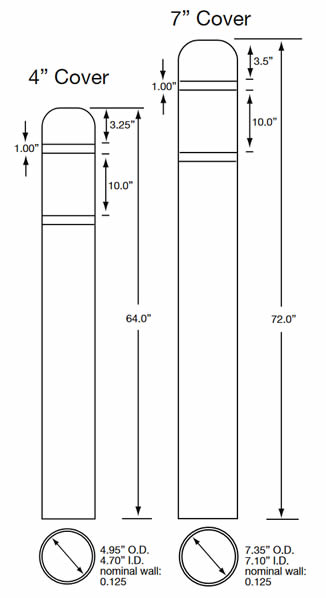

Model 1984-BC Bollard Covers

Model 1984-BC Bollard Covers (HDPE and MDPE) and 3M #680 reflective tape for durability and long service life.

(HDPE and MDPE) and 3M #680 reflective tape for durability and long service life.