IMPORTANT: EDGE DW Visigauge!!

At this time, OPW Edge DW Spill Container is being shipped without the Visigauge assembly due to a shortage from their vendor.

The product is being produced with a temporary plug cap in its place to allow the factory and the installer to perform the interstitial test to verify the integrity of the containment.

We apologize for the inconvenience and OPW will send out a replacement Visigauge to distributors who purchased this product. It will include a Visigauge assembly and one replacement o-ring seal.

Once you have received the Visigauge, please follow these instructions to install it. (Click here to read OPW’s Edge PDF)

Step 1: First, identify the temporary plug cap as the part with the hexagonal shaped head that is installed at the top of the round white gauge riser.

Step 2: Please unthread the temporary plug cap from the round white gauge riser.

Step 3: Next, install the replacement 0-ring onto the underside seat of the Visigauge as shown below.

Step 4: Finally, thread on the Visigauge into the white gauge adapter. This should be tightened to a quarter turn past finger tight.

Step 5: The Visigauge is now installed and the spill container can be vacuum tested to verify tightness.

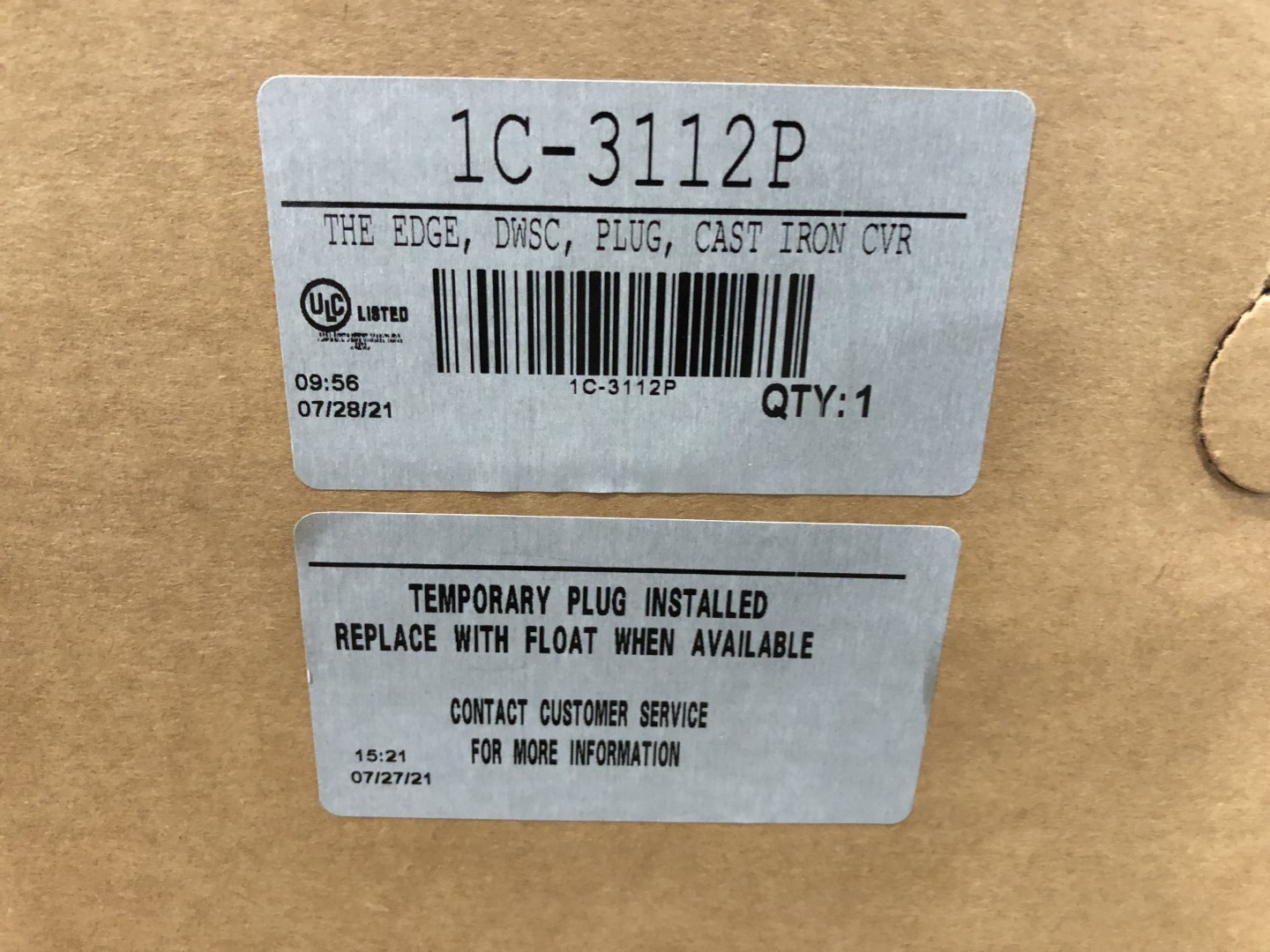

NOTE: Spill Containers with this plug installed will be identified with the below label beside the OPW part# label on the outside of the box.

Looking to purchase OPW products, you can find them online at johnwkennedyco.com ? Can’t find what you are looking for? Not to worry – feel free to contact us by email or give us a call at 1.800.238.1225.

|

|

|

|

|

|

| OPW Engineered Systems | Fibrelite | OPW Fuel Management Systems | OPW Retail Fueling |

The John W. Kennedy Company appreciates your business and continued support!

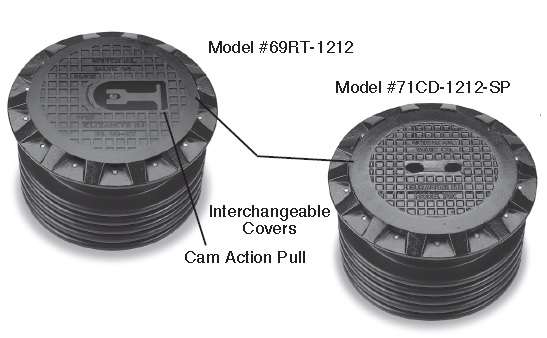

OPW has announced their new FibreTite Multiport Spill Containment System, which is now CARB EVR approved. These containers are designed with a lightweight composite cover for long-term water tight performance and meet all CARB and EVR requirements, as well as being certified for use on all existing standard gasoline Phase 1 Vapor Recovery Certification Phase 1 EVR Executive Orders. Among the features included are an integrated inspection port system, a removable flange in the container base, and a composite lift cover and optional levered plumber seal covers for easy access.

OPW has announced their new FibreTite Multiport Spill Containment System, which is now CARB EVR approved. These containers are designed with a lightweight composite cover for long-term water tight performance and meet all CARB and EVR requirements, as well as being certified for use on all existing standard gasoline Phase 1 Vapor Recovery Certification Phase 1 EVR Executive Orders. Among the features included are an integrated inspection port system, a removable flange in the container base, and a composite lift cover and optional levered plumber seal covers for easy access.