This is Veeder-Root’s fifth article in their series on what actually happens when you fill up at a gas station. Read the others here:

Behind the Scenes of Filling Up:

1. How Does it Work?

2. Gaining Approval and Getting Started

3. How does the fuel actually get to the nozzle?

4. How do gas stations ensure fuel isn’t leaking?

.

Keeping track of all that fuel

When you fill up at a gas station, it’s likely that you’re one of many people getting gas at the same time.

At busy gas stations and c-stores there are multiple transactions happening at one time. In fact, the average c-store dispenses just over 4,000 gallons of fuel per day!

With all that fuel pumping out of the storage tank, how does the site operator maintain an understanding of the current inventory, how much has been sold that day, and the amount of inventory that they started with? This basic information is what they will need for inventory reconciliation, which is the process of making sure that they can account for all the fuel that has been dispensed.

If there is a difference between the amount of fuel that records say are in the storage tank and the actual amount of fuel in the tank, then there is a fuel variance. There are two likely scenarios for the loss, either there is an adjusted loss or an actual physical loss of the fuel.

Adjusted losses accrue when key records of fuel transfer don’t match up. It’s common when the bills of lading, delivery confirmations, automatic tank gauges, and point-of-sale equipment may all supply a different record of the transaction. Contributing to the issue are tank charting and equipment errors, which can mask any actual fuel losses.

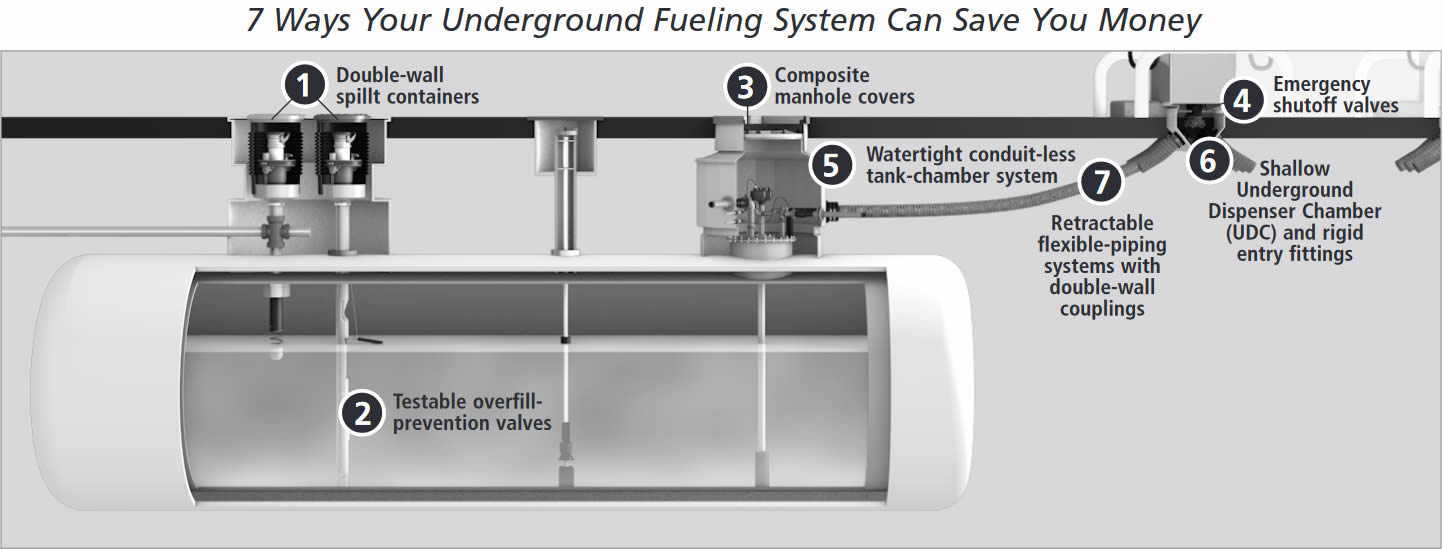

Physical loss might happen if there was a leak that went undetected, a meter drift, theft or delivery discrepancy, or even a change in temperature that causes fuel contraction or expansion in the tank.

What Can We Do About it?

The first step is to confirm that the equipment at your gas station is maintained and operating correctly. You then want to ensure that you have accurate tank charts for your site. The next step is to implement a daily reconciliation and variance tracking method.

C-Store owners should also take advantage of remote connectivity options that allow them to check on their inventory and site status from anywhere.

Automating The Process

The most accurate way to generate a tank chart is to use AccuChart on your Veeder-Root TLS Automatic Tank Gauge. This application takes frequent measurements and reports back when there is a statistically significant data set for creating an accurate tank chart.

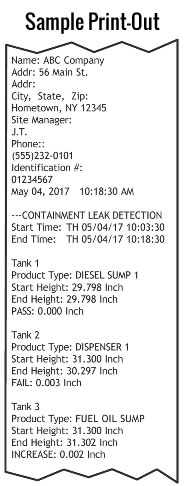

Once you have an accurate tank chart, an application like Business Inventory Reconciliation (BIR) can automatically calculate fuel variance.

BIR tracks all the fuel that enters or exits each of your underground tanks, accounting for all delivery and dispensing activity. It automatically collects metered sales information from electronic and mechanical dispensers and generates accurate delivery and reconciliation reports.

This is our final installment in our blog series on what actually happens when you fill up at a gas station. You can find more information on every step of the process here.

If you have any questions or would like to purchase Veeder-Root and Red Jacket Products, visit us online at www.johnwkennedyco.com or call us at 1.800.451.4021.

The John W. Kennedy Company appreciates your business and continued support!

Omntec offers the CLD Series portable containment sump tester, available in 3, 4, 6 , and 8 probe versions.

Omntec offers the CLD Series portable containment sump tester, available in 3, 4, 6 , and 8 probe versions.