Technical Support Notification

TLS4 Series Security Settings

Overview

The TLS4 Series consoles come with security features allowing for greater protection and control of access to the Automatic Tank Gauge. Features such as configurable user access and segmented network ports help ensure both network and front-panel security.

This update covers:

- User and Roles Admin

- Create User Accounts

- Custom Roles

- System Security

- Front Panel Security

- Serial Command Port (TCP/IP Interface)

- SSH Port

- Serial Command Over SSH

- HTTPS Port

- User Admin Via Web

- Router and Network Switch

User & Roles Admin

Create User Accounts & Custom Roles

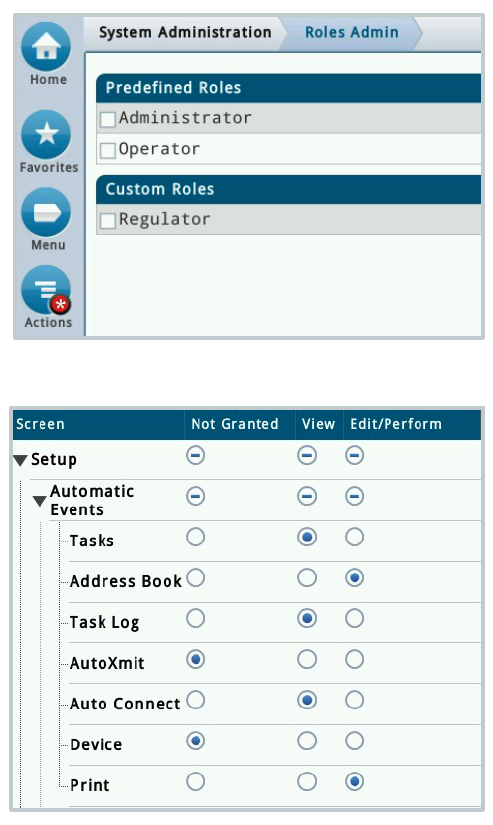

All TLS4 Series consoles come preconfigured with three roles: Administrator, Operator and Regulator. Additional custom roles can be programmed.

Menu –> System Administration –> Roles Admin

• Administrator: This role gives full access to the console – including the ability to create new roles and users.

• Operator: This role allows the user to view and generate reports and perform certain manual functions, such as starting a manual line or tank test.

• Regulator: This role allows the user to print and view console reports.

Note: Users assigned to the Regulator role cannot be deleted.

To add a Custom role, select Actions –> Add New Role

The Custom role allows each individual screen to be viewable, editable or not accessible. For example, in Setup under the Automatic Events section, each option can be customized:

Veeder-Root strongly recommends creating an Administrator account with a unique password. This will disable the default username and password.

Note: When using the Plus View or Remote View apps, the same login credentials are used.

Security

System Security

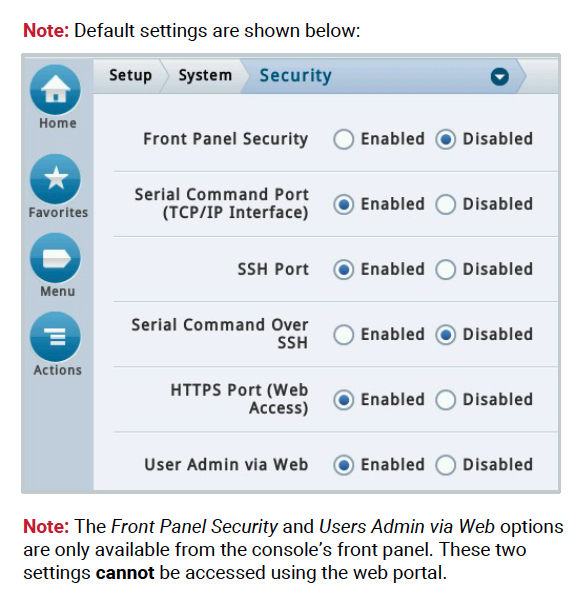

The TLS4 Series consoles have optional security features to enhance protection in addition to front panel security that requires a username and password, when enabled.

Front Panel Security: When disabled, all users can access all screens with no password required. When enabled, users must login with a password to gain access to the screens they’re allowed to view.

Serial Command Port (TCP/IP Interface): When disabled, the console will not accept any serial commands sent through a telnet session.

Note: This will not block all traffic on the TCP/IP port. It will only block serial commands.

SSH Port: When disabled, all traffic on the SSH port will be blocked.

Serial Command Over SSH: For the SSH Public Keys feature to work, this port and the SSH port must be enabled. By default, this port is disabled.

HTTPS Port (Web Access): When disabled, all traffic on the HTTPS port will be blocked. This will prevent access to the web portal, and the Plus View and Remote View apps.

User Admin via Web: When disabled, the System Administration screens will be blocked from the web portal – access to these two screens will only be available on the console’s front panel.

Router or Network Switch

Most routers or network switches have additional features allowing ports to be enabled or disabled. Contact device manufacturers or internet service providers (ISPs) for more information.

Download the TLS4 TSN Here

LOOKING FOR VEEDER-ROOT SYSTEMS & PARTS?

Well look no further – click on the Veeder-Root logo below to visit our web store, where we have hundreds of the most popular Veeder-Root items ready to buy in our webstore and if you can’t find it there, please contact us!

If you have any questions about TLS4 Series or would like to receive a quote for TLS4 Series or any other Veeder-Root system and/or parts , please feel free to contact us at 1-800-451-4021 or Email Us with any further questions or inquiries.

Franklin Fueling Systems has identified a potential issue with weeping fittings of certain FLEX-ING™ 1½” Flexible Connectors with NPT Male Swivel End Fittings manufactured between January 18, 2021 (work week 4 of 2021) and May 28, 2021 (work week 22 of 2021).

Franklin Fueling Systems has identified a potential issue with weeping fittings of certain FLEX-ING™ 1½” Flexible Connectors with NPT Male Swivel End Fittings manufactured between January 18, 2021 (work week 4 of 2021) and May 28, 2021 (work week 22 of 2021).