![]() Discover the world’s leading secondary containment repair solutions at Icon Containment Solutions

Discover the world’s leading secondary containment repair solutions at Icon Containment Solutions

Icon’s SplitRepair Fittings are designed to be the most simple approach to any configuration of equipment for faster installations, and we have solutions for any combination of sump type, entry/test fittings, and piping (offset or angled pipe).

![]()

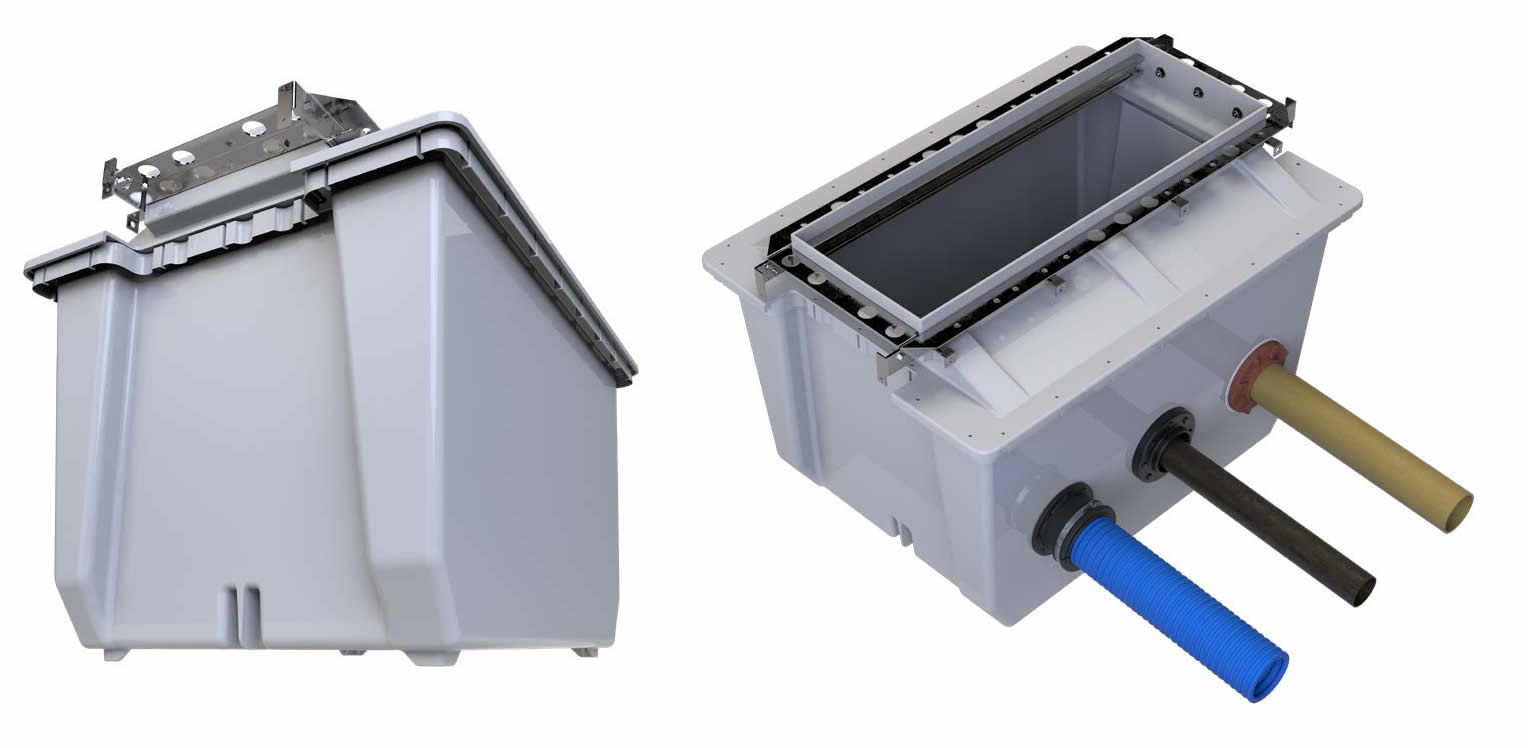

Sump leak repair vs equipment replacement provides obvious financial and operational advantages to the UST system owner and can be very profitable for the installing contractor. Icon’s entire mission is to help the installer be profitable and still provide significant savings to the owner.

Without a doubt, the conditions for sump repair can be challenging as access is often very limiting. When the sump is repairable, it can be completed successfully and efficiently with the correct applications and support.

GO WITH THE EXPERTSIcon is exclusively focused on Sump Leak Repair Solutions. Icon’s expertise and range of solutions for any configuration of equipment is unmatched. Use Icon as a resource to develop a more profitable repair business. |

SIMPLELess installation time in the sump with more reasonable workmanship requirements, and the lowest net cost to completion |

PROVENIcon direct replacement fitting designs and materials conform to EPA recognized Repair Standard (NLPA/KWA Standard 823) compatibility requirements |

PERMANENTSolutions backed by the Lifetime Warranty on all fittings installed by an Icon Certified Installer |

SERVICEIcon’s #1 priority with Icon direct and ongoing training and technical support for the installer – from initial site survey through testing after successful installation. Most fitting orders are shipped the same or next day from receipt of the order! |

Icon PROTEX Flexible Compression-Seal Repair Fittings have never shown any degradation of material through all independent testing and field application. And remember, PROTEX repair fittings can be installed in any ambient conditions and wet environments.

IBOND STRUCTURAL BONDER TECHNOLOGY

Icon Rigid Bonded-Seal Repair Fittings utilize IBOND structural bonder technology, which absorbs the kinetic energy from expansion/contraction, heave/settling, vibration, and shock movement in the pipe/sump connection better than any other bonded design, which also have never shown any degradation of material through all independent testing and field application.

Icon PROTEX Flexible Compression-Seal Repair Fittings have never shown any degradation of material through all independent testing and field application. Discover all of the advantages of PROTEX today!

WHY PROTEX? |

|

Lifetime Warranty Every Icon fitting is backed by the Life of Sump Warranty. |

PROTEX Made with PROTEX. Choose fitings designed to last. |

Tested and Approved Independently tested to exceed industry standards |

| LEARN MORE | LEARN MORE | LEARN MORE |

Feel free to call us at 1.800.451.4021 or email us using the link below to

LEARN MORE & GET A FREE QUOTE

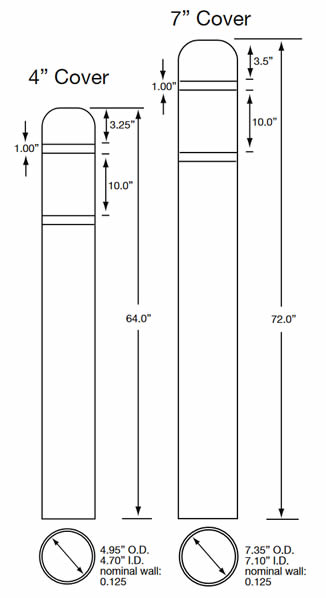

Model 1984-BC Bollard Covers

Model 1984-BC Bollard Covers (HDPE and MDPE) and 3M #680 reflective tape for durability and long service life.

(HDPE and MDPE) and 3M #680 reflective tape for durability and long service life.

Windows 7!

Windows 7!